1. Assessment

When evaluating where the actuator will be installed, it’s crucial to determine the type of motion required. For instance, the motion needed to open and close a door or valve differs from that required to activate a process on a machine. Actuators are designed to produce either straight-line or circular motion. Assessing the type of motion and how it integrates into your process is essential for selecting the right actuator.

2. Energy

Electrical actuators have been refined and optimized for a wide range of applications, making them the most popular and commonly used type. However, they may not be suitable for all conditions. In cases where power is limited or unavailable, it may be necessary to consider pneumatic or hydraulic actuators as alternatives.

3. Level of Precision

An actuator designed for use in outer space, where precision and accuracy are paramount, may not be suitable for heavy-duty applications in a factory setting. The choice of actuator often depends on the size and nature of the work. Small, delicate operations require actuators capable of precise movements, whereas tasks such as stacking pallets or managing a valve may not demand the same level of precision.

4. Force

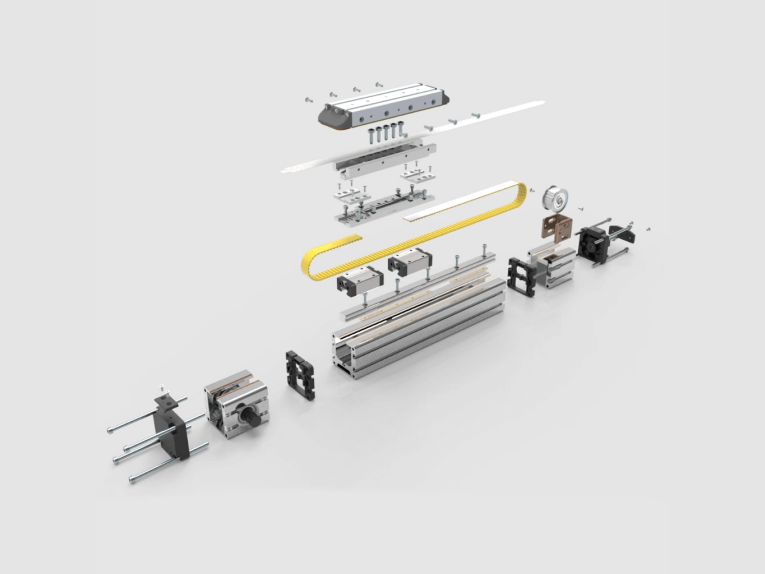

A primary function of an actuator is to deliver force to perform work, such as lifting, tilting, moving, activating, and sliding objects and materials. The extent of work an actuator can perform depends on the force required to move a load, which is defined by its load capacity. Manufacturers provide detailed information on their products’ load capacities, and this data should be carefully reviewed to ensure that the actuator meets the requirements of the job.

5. Movement

Actuators are available with various motors and stroke lengths. The stroke length is determined by the length of the shaft or lead screw. Before purchasing an actuator, it is important to assess the required amount of movement for the job to ensure the actuator meets those needs.

6. Speed

While speed is an important factor when selecting an actuator, it is also crucial to consider the weight that needs to be moved. When a substantial amount of force is required, the actuator will move more slowly. Speed is typically measured in distance per second. Calculating the necessary duty cycle can provide valuable data to help choose an actuator with the appropriate speed and performance to meet the work conditions.

7. Environment

Most actuators do not perform well in dirty, wet, moist, or dusty environments. While some models are designed to work underwater, most require protection in the form of enclosures or shelters to function effectively in unclean, rugged, or rough conditions.

8. Mounting

Each actuator features a distinct mounting style. For example, a dual pivoting mount positions the actuator on either side of the mounting point, allowing it to pivot. In contrast, a stationary mount enables the actuator to produce push or pull motions from a fixed position. Proper mounting is crucial for ensuring optimal performance and efficiency, and it should be carefully considered during the purchasing process.

Side loading occurs when force is applied radially to the actuator, which can lead to issues such as offset loads, inadequate fixed mounting, or loads pushing against the actuator. Problems associated with side loading include extension tubes pushing against the cover, rough ball nut operation, damage to gears, and actuator binding.

9. Space

If the space where an actuator is needed seems restrictive and confined, you might worry that an actuator won’t fit due to its size or length. However, there are actuators specifically designed for such conditions. Several manufacturers offer various types of telescoping actuators that are built to operate effectively in compact spaces.

Pin-to-pin mounting, with spherical bearings on both sides, provides maximum tolerance for misalignment. Higher-quality designs often include features that restrict roll around the actuation axis by limiting one of the spherical bearings to only two degrees of freedom, enhancing stability and precision.

10. Pin-To-Pin mounting

Using spherical bearings on both sides allows for maximum tolerance of misalignment. Higher-quality designs often feature constraints that limit roll around the actuation axis by restricting one of the spherical bearings to only two degrees of freedom.

Post time: Dec-02-2025