Linear Motors

These motors generate force directly along a linear path, using electromagnetic fields instead of mechanical contact.

1. Ironless Linear Motor

The ironless linear motor is built for applications where ultra-smooth, cog-free motion is a must. With no iron in the moving coil, this motor type eliminates magnetic attraction between the coil and stator, offering virtually zero cogging force and ultra-low inertia.

Key Benefits:

Ultra-precise movement, even at low speeds

No magnetic pull = longer bearing life and reduced vibration

Ideal for cleanrooms, semiconductor, laser cutting, and optical systems

When only perfection in motion is acceptable, ironless is the weapon of choice.

2. Ironcore Linear Motor

Need more thrust? Enter the ironcore linear motor. Built with an iron lamination core, this variant delivers higher continuous and peak forces ideal for moving heavy loads at high speeds. While it does produce some cogging, today’s motion controllers can effectively compensate for it.

Best suited for:

Large-format automation systems

High-speed industrial packaging

Automotive manufacturing

If you want muscle with precision, the ironcore motor brings both to the table.

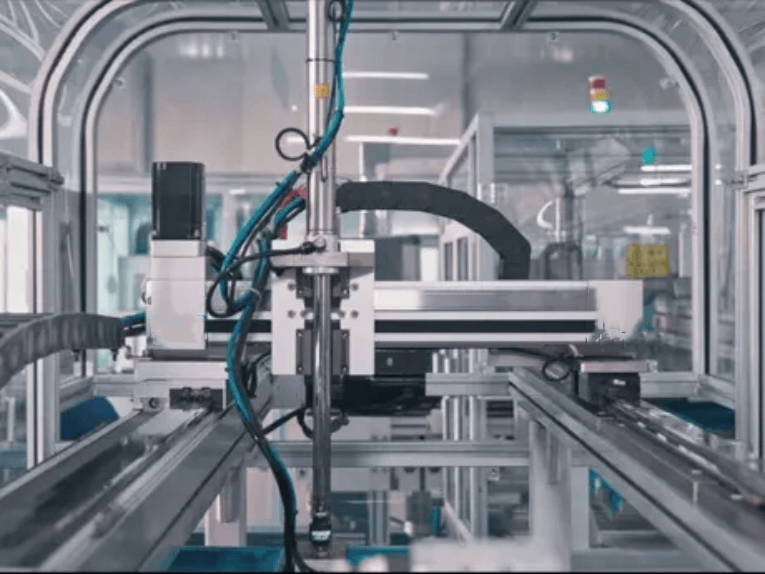

Advantages & Common Applications of Linear Motors

Direct-drive motion: No mechanical linkages = fewer points of failure

Minimal maintenance: No belts, screws, or lubrication required

High-speed, high-accuracy: Critical for industries like semiconductors, medtech, and electronics

Compact design: Shrinks machine footprint while enhancing throughput

Indirect Linear Motion Drives

For many industries, these systems translate rotary motion (from a motor) into linear movement using mechanical elements.

1. Ball Screw & Lead Screw Systems

These are the workhorses of traditional linear motion. Ball screws use recirculating ball bearings to minimize friction, while lead screws offer simplicity and cost-efficiency.

Ball Screw Benefits:

High positioning accuracy

Efficient power transmission

Suitable for CNC machines, 3D printers, and machine tools

Lead Screw Advantages:

Lower cost

Self-locking (no back-drive)

Great for vertical applications or low-duty cycles

If your project calls for precision without complexity, ball and lead screws remain reliable, proven choices.

2. Belt-Driven Actuators

These systems use a toothed belt and pulley mechanism to deliver fast, repeatable motion over spans of several meters.

Ideal for:

Conveyor systems

Light pick-and-place operations

Packaging and material handling

Strengths:

High speed and low noise

Cost-effective over long strokes

Easy maintenance and modular design

3. Rack and Pinion Systems

For applications requiring high torque linear motor and rugged reliability, rack and pinion drives provide the force. This mechanism involves a gear (pinion) engaging with a linear gear track (rack), converting rotary motion into powerful linear displacement.

Where it shines:

Heavy-duty automation

Large-scale industrial machines

Environments with harsh operating conditions

Post time: Oct-27-2025