Linear motion isn’t just about moving in a straight line, it’s about moving smarter, faster, and with greater precision than ever before. From high-speed production lines to ultra-accurate medical devices, its impact spans across industries, enabling innovation and operational excellence. As you explore different classifications and applications, the key is to match the right linear motion system to your performance goals. In an increasingly competitive and automated world, investing in the right motion technology isn’t just an upgrade, it’s a strategic advantage.

Advantages

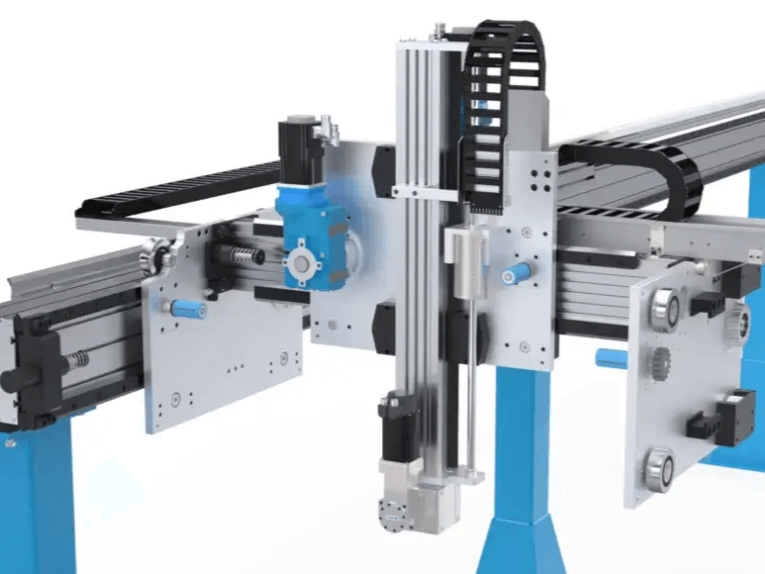

1. High speed and precision: Linear motion drives offer fast, accurate, and repeatable positioning. With direct-drive movement and no mechanical conversion, they deliver micron-level precision for critical applications in electronics, medical devices, and automation.

2. No backlash and low maintenance: With fewer moving parts and no mechanical contact, these systems eliminate backlash and reduce wear. This results in smoother motion, less maintenance, and significantly longer operational life.

Disadvantages

1. High initial cost: Cutting-edge performance comes with a premium price. While linear motion technology is a smart long-term investment, the upfront cost is higher than traditional mechanical alternatives.

2. Requires precise installation: Proper alignment and calibration are critical. Any misalignment can impact system accuracy and durability, making professional setup a must.

3. Limited travel in some configurations: Certain linear motion systems, such as ironless motors, may have restrictions on maximum stroke length. For long-range movement, alternative system types may be more suitable.

Post time: Nov-11-2025