Linear Modules, a crucial component in automation technology, operate based on some fundamental principles. This section explores the basic operation and key components that drive the functionality of Linear Modules.

Understanding the Working of Linear Modules - A proper understanding of how Linear Modules function is essential to appreciate their role in various industrial applications, as well as to make informed decisions in their selection, installation, and maintenance.

Basic Operation

At its core, a Linear Module converts rotary motion into linear motion.

Mechanics of Conversion from Rotary to Linear Motion - In the case of a ball screw or belt-driven Linear Module, a motor’s rotary motion is transferred to the ball screw or belt, which then moves the carriage linearly along the guide. In a linear motor-driven module, the linear motion is directly generated, bypassing the need for conversion.

Key Components

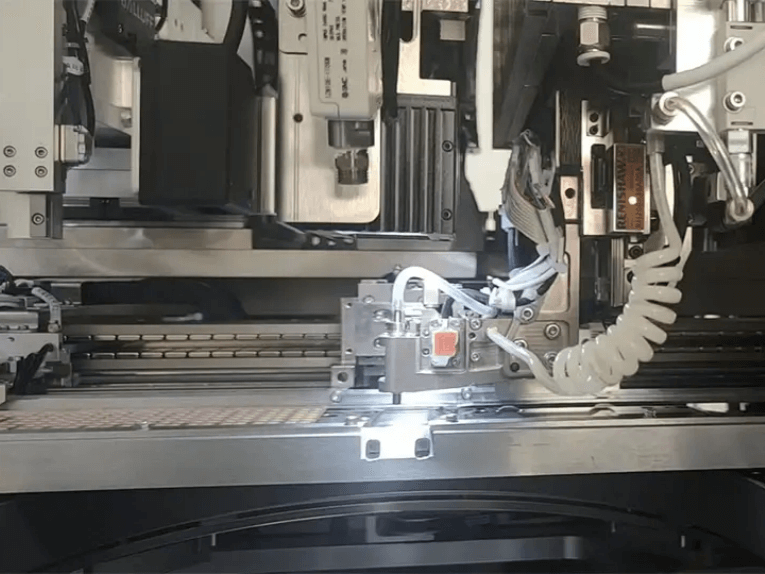

A typical Linear Module consists of several key components that collectively enable its functionality. These include a guide or rail, a drive mechanism, and a carriage.

1. Guide or Rail - The guide or rail is a foundational part of a Linear Module. It guides the carriage and provides the path along which the carriage moves.

2. Drive Mechanism - The drive mechanism, which could be a ball screw, belt, or linear motor, is responsible for generating the linear motion. The type of drive mechanism used can significantly impact the Linear Module’s performance characteristics, such as speed, precision, and load capacity.

3. Carriage – The carriage is the component that moves linearly along the guide or rail. It often has a mounting surface to which the payload — the item that the Linear Module is designed to move or manipulate — is attached.

Post time: Feb-02-2026