What OEMs and design engineers need to know about motors, drives, and controllers.

Whether designers are improving a motion-centric machine or building a new one, it is essential they begin with motion control in mind. Then they can develop the design around the best way to get effective and efficient automation.

Motion-based machines should be designed and built around their core functions. For a printing machine that relies on a specific set of winding applications, for example, designers would focus on the critical parts and develop the rest of the machine in support of the core functions.

This sounds like Design Engineering 101, but with time-to-market pressures and teams traditionally siloed into mechanical, electrical, and software departments, it’s easy for design to revert to a largely linear process. Designing with motion control in mind, however, requires a mechatronics approach that includes developing the initial concepts, determining the system topology and machine approach, and selecting the connection interface and software architecture.

Here are some essential aspects of motors, drives, controllers, and software that engineers should consider from the beginning of every machine design project to reduce inefficiencies, errors, and cost while making it possible for OEMs to solve customer problems in less time.

【The Design Process】

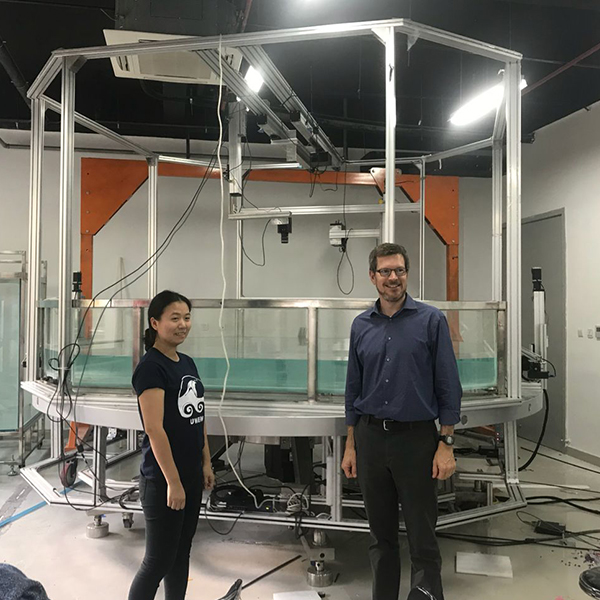

How and where parts move is typically where engineers spend most of their engineering effort, especially when developing innovative machines. Although innovative builds are by far the most time-consuming, they often offer the biggest ROI, especially if teams make use of the latest in virtual engineering and modular designs.

The first step when developing a machine from scratch is to ask: What are the critical functions of this machine? It could be to make a machine that is easy-to-clean, low maintenance, or highly accurate. Identify the technology that will deliver the required function, performance, or maintenance level.

The more complex the problem that needs to be solved, the more difficult it will be to determine the most vital functions. Consider working with a motion-centric automation supplier that can help define the critical details and determine the right approach.

Then ask: What are the machine’s standard functions? Staying with the earlier printing machine example, the tension and sensor controls used to unwind the material being printed on are fairly standard. In fact, about 80% of a new machine’s tasks are variations on past machines’ tasks.

Using modular hardware and code programming to handle the engineering requirements for standard functions significantly reduces the amount of design resources needed to complete the project. It also uses time-proven functions, thus increasing reliability and letting you focus on more complex parts of the design.

Working with a motion control partner that can deliver standard functions with modular hardware and software means you can focus on the value-added features that distinguish your product from the competition’s.

In a typical design project, mechanical engineers build the machine’s structure and its mechanical components; electrical engineers add the electronics, including drives, wires, and controls; and then software engineers write the code. Every time there’s a mistake or problem, the project team has to backtrack and correct it. So much time and energy in the design process is spent re-doing design based on changes or mistakes. Luckily, designing mechanics with CAD software and siloed planning and design are nearly things of the past.

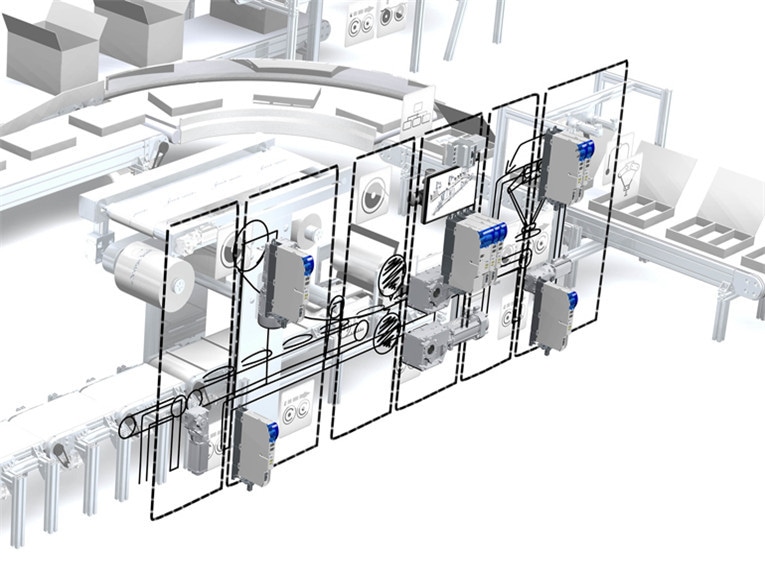

Today, virtual engineering lets teams design how machines will work using several parallel paths, thus dramatically shortening the developing cycle and the time-to-market. By creating a digital twin (a virtual representation of the machine), each department can work on its own and develop parts and controls concurrently with the rest of the team.

A digital twin lets engineers quickly test various designs for a machine as well as your machine technologies. For example, perhaps a process requires material be fed into a machine feed until the desired amount is collected and then the material is cut; that means you must figure out a way to halt the feed whenever the material needs to be cut. There are several ways to handle that challenge, and all of them may affect how the overall machine operates. Trying different remedies or relocating components to see how it affects operations is simple with a digital twin and leads to more efficient (and less) prototyping.

Virtual engineering lets design teams all see how the entire machine and its overlapping concepts work together to reach a particular goal or goals.

【Selecting the Topology】

Complex designs with several functions, more than one axis of motion and multi-dimensional movement, and faster output and throughput make system topology just as complicated. Choosing between centralized, controller-based automation or decentralized, drive-based automation depends on the machine being designed. What the machine does, both its overall and local functions, affects whether you opt for centralized or decentralized topology. Cabinet space, machine size, ambient conditions, and even installation time also affect this decision.

Centralized automation. The best way to get coordinated motion control for complex machines is with controller-based automation. Motion-control commands are usually forwarded to specific servo-inverters via a standardized real-time bus such as EtherCAT, and inverters drive all the motors.

With controller-based automation, several motion axes can be coordinated to perform a complex task. It is ideal topology if motion is at the heart of the machine and all parts must be synchronized. For example, if it’s critical for each motion axis to be in a specific place to get to properly position a robot arm, you’ll likely choose controller-based automation.

Decentralized automation. With more compact machines and machine modules, decentralized motion control reduced or eliminates the load on machine controls. Instead, smaller inverter drives assume decentralized control responsibilities, an I/O system evaluates control signals, and a communication bus such as EtherCAT forms an end-to-end network.

Decentralized automation is ideal when one portion of the machine can take responsibility for completing a task and doesn’t have to constantly report back to central control. Instead, each portion of the machine performs quickly and independently, only reporting back once its task is complete. Because each device handles its own load in such an arrangement, the overall machine can take advantage of more distributed processing power.

Centralized and decentralized control. Although centralized automation provides coordination and decentralized provides more efficient distributed processing power, a combination of both is sometimes the best choice. The final decision depends on overarching requirements including goals related to: Cost/value, Throughput, Efficiency, Reliability over time, Safety specifications.

The more complex the project, the more important it is to have a motion control engineering partner that can give advice on the different aspects. When the machine builder brings the vision and the automation partner brings the tools, that’s when you get the best solution.

【Machine Networking】

Establishing clean, future-proof interconnectivity is also a key step in designing with motion control in mind. The communication protocol is just as essential as where motors and drives are located because it’s not just about the what the components do—it’s also how you connect it all.

A good design reduces the number of wires and the distance they must go. For example, a set of 10 to 15 wires going to a remote terminal could be replaced with an Ethernet cable using an industrial communication protocol such as EtherCAT. Ethernet isn’t the only choice, but whichever one you use, ensure you have the right communication tools or buses, so you can use common protocols. Picking a good communication bus and having a plan for how everything will be laid out makes future expansions that much easier.

Focus on building a good design inside the cabinet from the start. For example, don’t put power supplies near electronic components that might be affected by magnetic interference. Component with high currents or frequencies can generate electrical noise in wires. So, keep high-voltage components away from low-voltage components for the best operation. Additionally, find out if your network is safety rated. If not, you’ll likely need hardwired redundant safety connections so if one part fails, it detects its own failure and reacts.

As the Industrial Internet of Things (IIoT) takes hold, consider adding advanced functions you or your customers may not quite be ready to use. Building the capabilities into the machine means it will be easier to upgrade that machine later.

【Software】

According to industry estimates, it won’t be long before OEMs will need to spend 50-60% of their machine development time focused on software requirements. The evolution from a focus on mechanics to a focus on interface puts smaller machine builders at a competitive disadvantage, but can also level the playing field for companies willing to adopt modular software and standardized, open protocols.

How software is organized can expand or limit what a machine can do now and into the future. Like modular hardware, modular software improves the speed and efficiency of machine building.

For example, say you are designing a machine and want to add an extra step between two phases. If you’re using modular software, you can simply add a component without reprograming or recoding. And, if you have six sections all doing the same thing, you can write code once and use it across all six sections.

Not only is designing more efficient with modular software, it also lets engineers deliver the flexibility customers crave. For example, say the customer wants a machine that runs different sized products, and the largest size necessitates a change in how one section functions. With modular software, designers can simply change out the section without affecting the rest of the machine’s functions. This change could be automated to let the OEM, or even the customer, quickly switch between machine functions. There’s nothing to reprogram because the module is already in the machine.

Machine builders can offer a standard base machine with optional features to meet each customer’s unique requirements. Developing a portfolio of mechanical, electrical, and software modules makes it easier to quickly assemble configurable machines.

To get the most efficiency from modular software, however, it is essential to follow industry standards, especially if you’re using more than one supplier. If the drive and sensor supplier aren’t following industry standards, then those components can’t talk to each other and all the modularity efficiencies are lost in figuring out how to connect the parts.

Additionally, if your customer plans on connecting the data stream to a cloud network, it’s essential any software is created using industry standard protocols, so the machine can work with other machines and interface with cloud services.

OPC UA and MQTT are the most common standard software architectures. OPC UA enables near-real-time communication between machines, controllers, the cloud, and other IT devices, and is probably the closest to a holistic communication infrastructure you can get. MQTT is a more lightweight IIoT-messaging protocol that enables two applications to talk to each other. It is often used in a single product—letting, for example, a sensor or a drive pull information from a product and send it to the cloud.

【Cloud Connectivity】

Interconnected, closed-loop machines are still the majority, but factories fully networked to the cloud are growing in popularity. That trend could raise the level of predictive maintenance and data-driven production and is the next major change in factory software; it starts with remote connectivity.

Cloud-networked plants analyze data from different processes, different production lines, and more to create more complete representations of production process. This lets them compare the overall equipment effectiveness (OEE) of various production facilities. Cutting-edge OEMs work with trusted automation partners to offer cloud-ready machines with modular Industry 4.0 capabilities that can send out the data end-users need.

For machine builders, using motion control automation and taking a holistic, total-process approach to make customers’ plants or companies more efficient will be sure to win more business.

Post time: Jun-24-2019