1.Requirements for Feed Systems in Modern High-SpeedMachining

In modern high-speed machining, the feed system is critical. It must provide precision at very high speeds, handle rapid changes in direction, and maintain these capabilities for long periods without noticeable wear. The goal is to cut cycle time while improving production quality and efficiency.

2.Why Linear Motors Are a Promising Solution for Fast Feed Systems

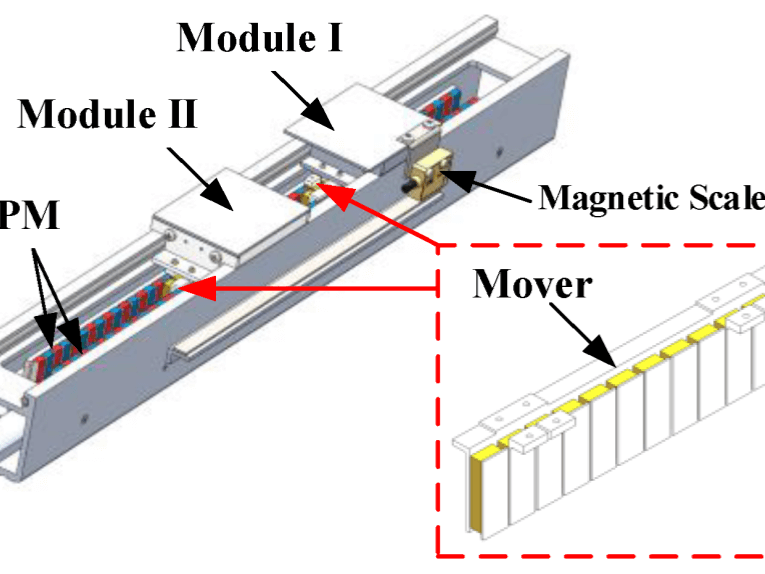

Linear motors have emerged as the most promising solution to meet these stringent requirements. Unlike traditional systems that rely on mechanical components such as ball screws or belts, linear motors offer direct drive capabilities. This direct approach reduces the number of parts that can wear out or fail. It also improves reliability and precision.

3.Advantages of Linear Motor Feed Drives

Precision and Accuracy

Linear motors excel in providing extremely precise motion. They convert electrical energy directly into motion, minimizing mechanical losses and errors typically caused by component wear.

Speed and dynamics

The ability of linear motors to speed up and decelerate quickly is a significant advantage in reducing cycle times. These motors do not have the inertia of heavy mechanical parts and can adjust speed and position quickly and accurately.

Reduced maintenance

Compared with traditional systems, linear motors have fewer moving parts. This makes it need less maintenance. This not only reduces downtime but also reduces long-term operating costs. Overall, it has more economic advantages.

Linear motors provide unparalleled speed, precision and reliability. It redefines the parameters of high-speed machining. Their integration with machine tools marks a major leap in manufacturing technology and breaks through the limits of automated production.

4.Advances in Linear Motor Technology and Drive Control

Technology Improvements: Recent developments in linear motor technology include improvements in magnet materials and coil design. This improves the efficiency and power density of these motors. The use of rare earth magnets, such as neodymium, improves force output and thermal performance. This enables linear motors to operate at higher speeds without overheating.

Advances in Drive Control: Drive control technology has also made great progress. Modern controllers now have more sophisticated algorithms. It can finely adjust the motor’s response to dynamic load changes and vibrations. This precision is critical for applications that need extremely fine motion. These controllers can also integrate more seamlessly with digital manufacturing systems, supporting Industry 4.0 initiatives.

Post time: Jan-12-2026