How Linear Motion Works

What is linear motion, really? It’s the controlled movement of an object in a straight line with no curves, no compromises. In the context of modern engineering, linear motion represents precision, power, and performance without rotational conversion. This is not just physics; it’s the foundation of high-efficiency automation.

The mechanism behind linear motion is straightforward but powerful: a drive system either mechanical (screw, belt) or electromagnetic (linear motor) generates force that propels a moving element along a linear guide. The motion is governed by a control system that dictates position, speed, and acceleration based on real-time feedback.

But here’s where the magic happens: force, friction, and accuracy don’t just influence performance they define it.

Force determines how much load can be moved and how quickly.

Friction impacts smoothness, energy efficiency, and component wear.

Accuracy ensures the position is reached to the micrometer every time.

In high-stakes environments like semiconductor assembly or surgical robotics, even a minor deviation can be catastrophic. That’s why linear motion technology is engineered for zero backlash, near-frictionless travel, and unparalleled repeatability.

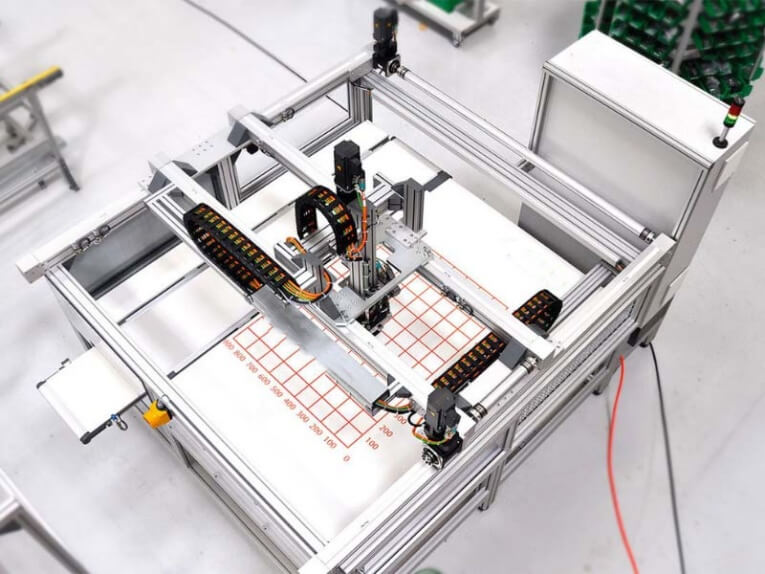

The Core Architecture of Linear Motion Systems

Every high-performance linear motion system is built on a robust architectural foundation. Whether you’re designing a compact lab instrument or a large-scale manufacturing robot, the same critical components apply:

1. Linear Guides – The Backbone of Motion

Linear guides provide the structural path for movement. Their job? Deliver smooth, stable, and accurate guidance, even under heavy loads or high speeds. High-quality guides minimize vibration and deflection key to long-term reliability in demanding applications.

Benefit: Keep your operations aligned and friction-free, no matter the distance or force involved.

2. Actuators – The Power Unit

Actuators are the muscle of the system. This is where motion is generated—either mechanically (ball screw, lead screw, belt) or directly (ironless/ironcore linear motion drives). They convert energy into straight-line movement with precision and power.

The choice of actuator determines:

Load capacity

Acceleration/deceleration profiles

Resolution and travel range

Choose right, and you unlock maximum productivity.

3. Encoder, Controller & Driver – The Brain of the System

This is where smart meets strong. The linear motion control system consists of:

Encoders to track real-time position and velocity

Controllers to process commands and trajectory paths

Drivers to deliver accurate electrical signals to the actuator

Together, these elements form a closed-loop system that ensures error-free, dynamic motion control, critical in industries where precision equals profit.

Post time: Oct-21-2025