-

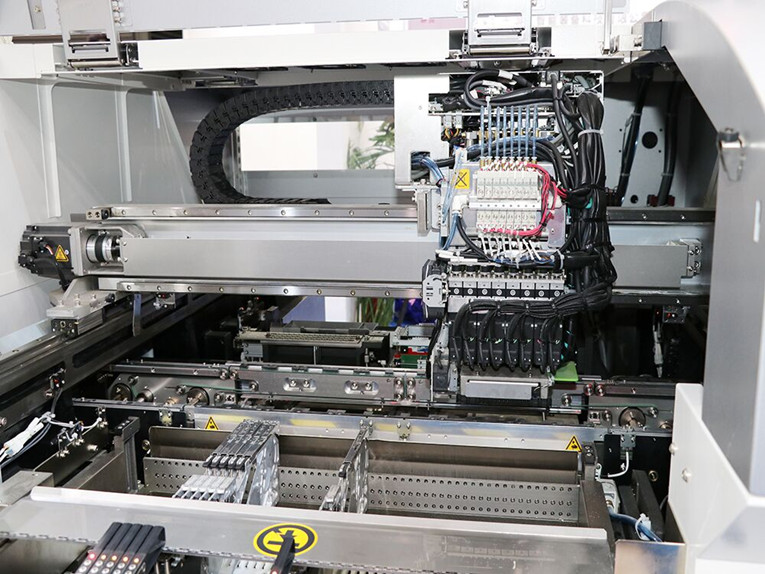

Linear Motion Systems for Heavy Automation and Pick and Place

This XZ gantry incorporates a rack drive in the slide, eliminating the need for a separate rack. The Z axis telescopes, useful when overhead height is limited. Which technology makes sense depends on many factors, including the operating environment, ease of installation, maintenance, and cost. ...Read more -

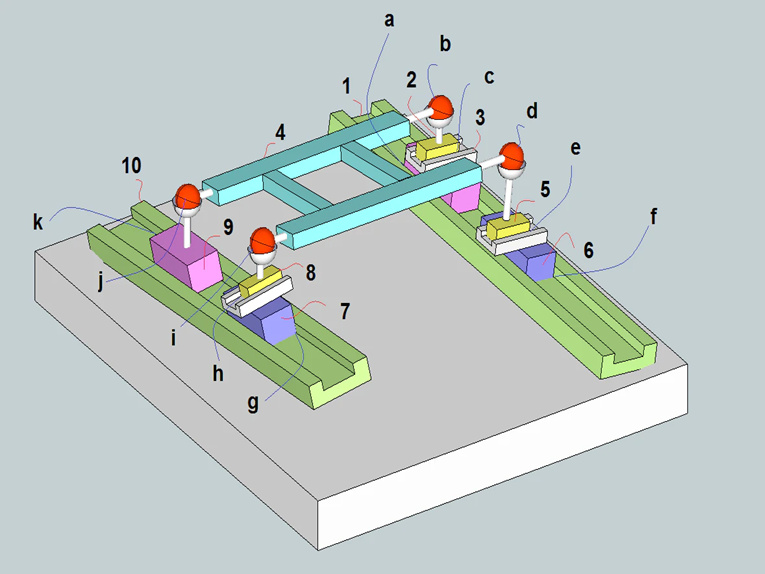

Keeping Gantries on the Straight and Narrow

Economical misalignment-compensation techniques prevent bearing overload and premature gantry failure Gantry Alignment Tools When positioning-system manufacturers build a gantry system, they typically use special alignment tools during the assembly process to ensure they meet force, precision, an...Read more -

Linear Motors: Leading a New Industrial Revolution

Linear motors are proliferating. They give machines the absolute highest precision and dynamic performance. Linear motors are very quick and precise for positioning, but are also capable of slow, constant-traverse speed for machine heads and slides, as well as tool and part-handling systems. A v...Read more -

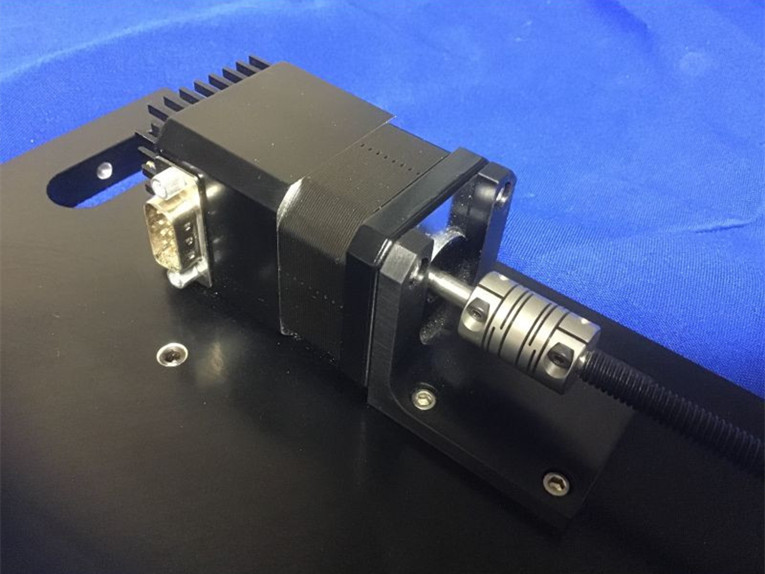

Infrequently Asked Questions About Linear Actuators

Here are a couple of questions engineers and designers should ask before choosing linear actuators. Designers getting ready to choose a linear actuator for a specific device or machine should have a list of questions ready to ask suppliers and manufacturers of those devices. These lists usually ...Read more -

Motion Control – A shortcut to sizing motors

Motor constant aids in selecting dc motors in motion-control applications. Brushed and brushless dc motors are a good choice in power sensitive or efficiency craving applications. A lot of times, a dc motor or generator data sheet will include the motor constant Km, which is the torque sensitivi...Read more -

What Offers Precise Positioning and Highly Dynamic Response for Motion-Control Task?

Linear Motor is the Key Answer. Linear motors offer precise positioning and highly dynamic response for many motion-control tasks. For machine tools, these include not only rapid traverse, but slow, constant-speed movement of machine heads, spindle slides, tool-management systems, and part-handl...Read more -

What is the Difference Between Industrial Robots?

As the world of robots expands in the industrial space, it’s prudent to get to up to speed on the multiple types available and their capabilities. In today’s industrial automation field, robots handle difficult, dangerous, and repeated tasks. These jobs include the lifting of heavy objects, pick...Read more -

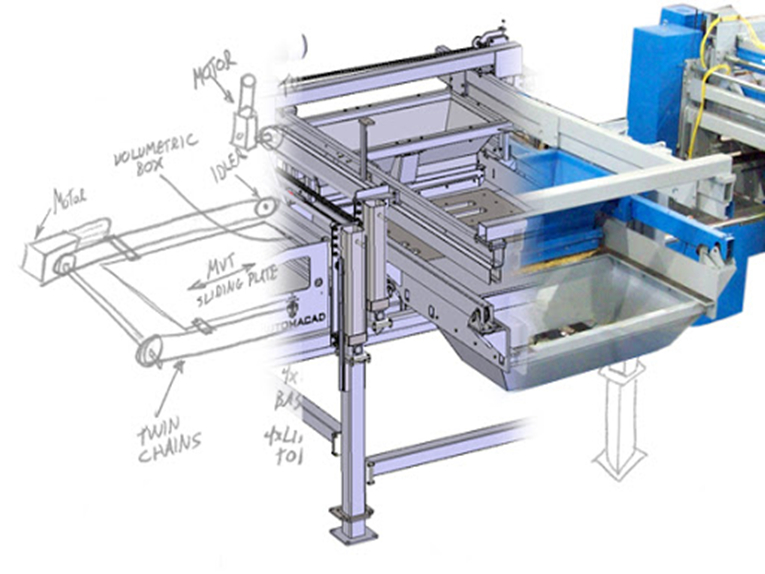

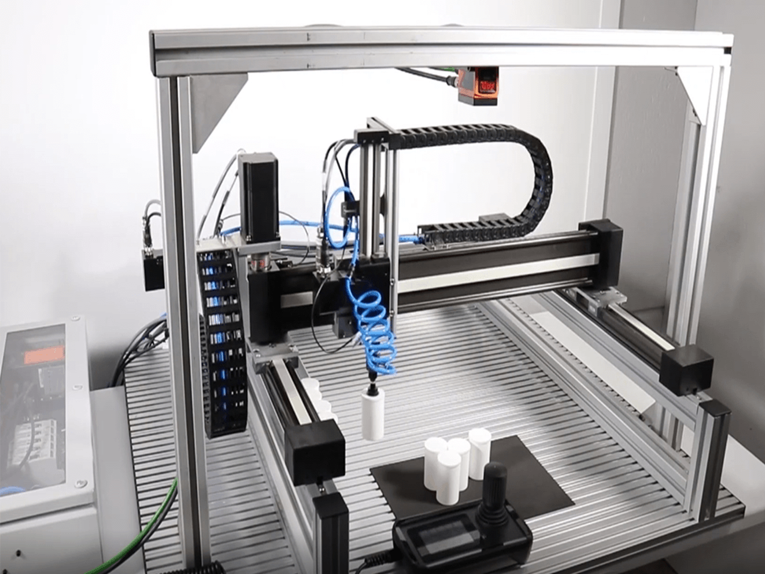

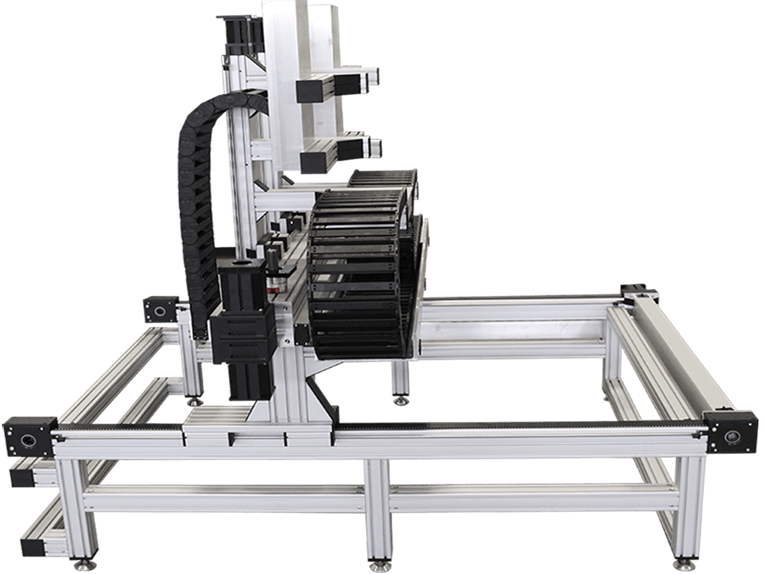

How to Carry Out the Implementation of Custom Linear Positioning System?

In the previous article, we focused on the importance of the program design stage and Fuyu’s own process specifications for non-standard design. So how do we carry out implementation after the plan is determined? First, let’s imagine a situation, in Fuyu’s production workshop, the internal...Read more -

Sizing and Selecting Linear Motion Systems

How “LOSTPED” Can Help? From packaging and material handling to semiconductor fabrication and automotive assembly, virtually all manufacturing processes incorporate some type of linear motion, and as manufacturers become familiar with the flexibility and simplicity of modular linear ...Read more -

Achieving Hazard-Free Linear Motion

The safety case for electromechanical actuators over hydraulic cylinders. Linear motion machine designers are increasingly specifying electromechanical actuators because they are cleaner, easier to control and require less maintenance than hydraulic cylinders. Often overlooked, however, are the...Read more -

Two Drives Yield Precise Dual-Speed Motion

Highly precise linear positioning systems, such as those used to focus and scan in measuring and inspection equipment often need two different motion modes: a rapid one (100 mm/sec) followed by a slower one (20 nm/sec). The fast mode reduces move time, while the slower mode ensures precision. U...Read more -

Timing Belts in Linear Positioning System

Belt and pulley pitch, Belt length and center distance. Reinforced urethane timing belts work well in high-accuracy linear motion and conveying applications because they stretch very little, do not creep or slip, and are much stiffer than neoprene, which means less tooth deflection. In linear po...Read more