A linear motor is often described as a rotary motor, just cut up and rolled out so that instead of a rotating shaft creating torque, it’s a load moving linearly that creates force. Linear motors use magnetic levitation to move an object – this way it is not slowed down by friction and can actually achieve more precise control than mechanical options.

This may remind you of high-speed trains that levitate on a set of magnetic tracks – the concept of linear motors is similar, except the force generated is put to use in a variety of ways in the industrial sector.

Types of Linear Motors

Linear motion can be achieved with a few different motor designs. Either a forcer or the magnetic track can move linearly to create force, depending on the design, although most designs use a forcer for motion. While the concept of linear motors is the same across all types, the resulting force, control and efficiency varies. There are three main types of linear motors:

1. Cylindrical linear motors: these were some of the first commercially available linear motors. They’ve lost favor in the industrial sector, however, because their length is inherently limited by design. The only point of support is at the ends of a cylindrical rod, meaning the magnet will contact the forcer if the motor design is too long.

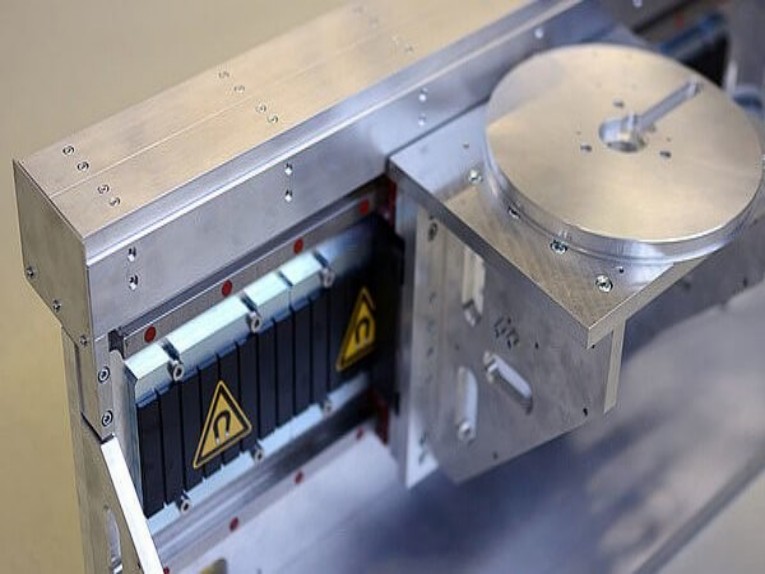

2. U-channel linear motors: these linear motors have two parallel magnet tracks facing each other, creating a U-shape, with the forcer supported by a bearing system between the tracks. This design is widely used because it minimizes magnetic flux leakage, increasing efficiency.

3. Flat linear motors: these types of linear motors feature a flat track below a forcer. There are a few different versions of flat linear motors:

a. Slotless ironless flat motors: a series of coils mounted on an aluminum base make up this type of linear motor. The lack of iron in the forcer means the motor has no attractive force. These motors provide great control but have low outputs of force.

b.Slotless iron flat motors: the only difference in design from the ironless flat motor above is that this motor has its coils mounted on iron laminations. This creates an attractive force between the track and the forcer, increasing the amount of force produced.

c.Slotted iron flat motors: in this design, the coils are enclosed by a steel structure on the track. This creates a more focused magnetic field, which is what makes these types of flat motors the most powerful. However, they’re also the most susceptible to wear over time.

Most linear motors are used for machine tools or the manufacturing of semiconductor components where their precision and speed creates major productivity gains. The three types of linear motors listed above are the main motor designs used in the industrial sector.

Linear motors are a relatively new motor, but they’re already finding widespread use. The use of magnetic levitation reduces wear, which in turn reduces downtime and maintenance frequency. There are many benefits to using linear motors.

Post time: Jul-03-2023