Linear motion refers to the movement of an object or component along a straight path, a concept that lies at the core of countless automation systems today. From CNC machines and robotic arms to advanced medical devices and semiconductor production lines, linear motion systems enable fast, precise, and repeatable operations.

What is Linear Motion?

Linear motion is the backbone of modern automation. It refers to motion along a straight path, as opposed to rotary motion which occurs around an axis. Whether it’s in high-speed packaging, precision robotics, or semiconductor manufacturing, linear motion systems are the invisible engine driving performance, speed, and accuracy.

In the context of industrial automation, linear motion is not just a mechanical concept—it’s a strategic advantage. With the right linear motion control systems and drives, businesses can execute ultra-precise positioning, seamless material transport, and synchronized multi-axis coordination at scale.

There are several types of linear motion systems, including:

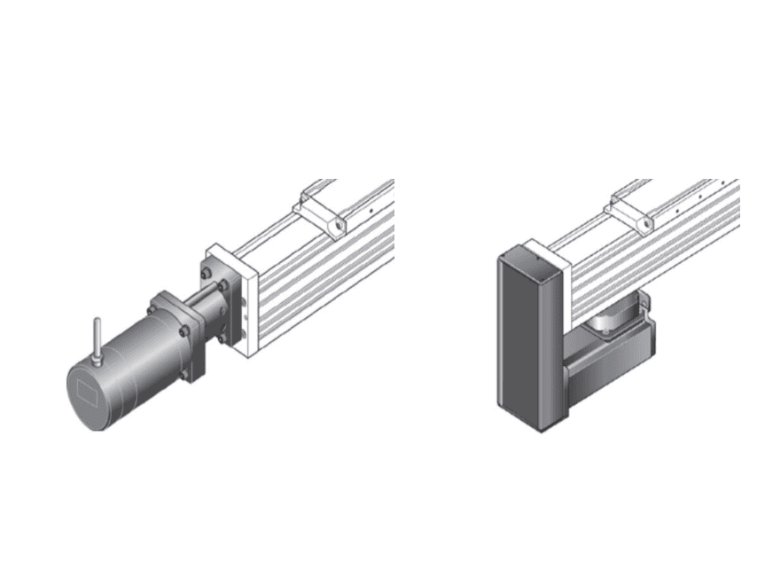

1. Direct-drive systems using linear motors (e.g., ironless or ironcore),

2. Ball screw or lead screw systems for mechanical actuation,

3. Belt-driven systems for longer travel ranges with moderate accuracy.

Each technology delivers unique benefits, depending on the application demands for force, accuracy, and cost efficiency.

Why Linear Motion Is Critical in Automation and Engineering

The linear motion industry has exploded alongside the demand for smarter, faster, and more precise automation. From medical imaging equipment to industrial robots, linear motion technology plays a vital role in enabling compact designs, reducing maintenance, and pushing throughput to the limits.

Here’s why you should care:

1. Unmatched precision: Execute movements with micrometer accuracy.

2. Zero backlash: Eliminate mechanical gaps for ultra-smooth operations.

3. High repeatability: Achieve consistent performance every single time.

4. Scalable design: Adapt from small lab systems to massive production lines.

In an era where downtime costs dollars and every millisecond counts, choosing the right linear motion drives can directly influence your bottom line.

Linear Motion vs Rotary Motion: What’s the Difference?

While rotary motion involves spinning around an axis (like a motor shaft), linear motion is all about moving straight whether that’s up/down, in/out, or side to side. Rotary motion is great for rotation-driven tools or wheels, but when precision placement or straight-line travel is required, linear motion is the clear winner.

When Should You Choose Linear Over Rotary?

Choose linear motion technology when your application demands:

1. Precision movement over a defined axis

2. High dynamic responsiveness without mechanical conversion losses

3. Smooth, vibration-free operation (e.g., in optics or cleanrooms)

Real-World Examples:

1. In semiconductor fabs, ironless linear motors power wafer handlers with zero cogging.

2. In pick-and-place machines, belt-driven linear actuators ensure fast, reliable part movement.

3. In medical scanners, high-precision linear stages control scanning arms for accurate diagnostics.

Post time: Oct-11-2025