What is a gantry system?

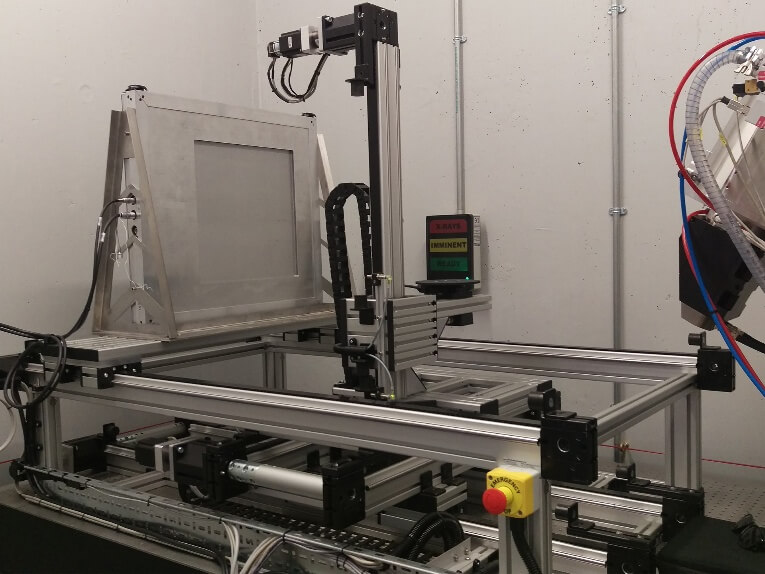

A gantry system is a mechanical structure designed to move objects or tools in one or more linear or rotary axes. It is typically comprised of a framework, linear rails or guides, and motors, which work together to provide precise and controlled motion.

What are the different types of gantry systems?

The three main types of gantry systems are Cartesian, polar, and cylindrical. Cartesian gantry systems consist of linear rails arranged in orthogonal axes (X, Y, and Z), while polar systems use a combination of a rotary axis and a linear axis. Cylindrical gantry systems, on the other hand, employ a linear axis and a rotary axis arranged in a cylindrical configuration.

What are the primary design considerations for gantry systems?

Key design considerations for gantry systems include load capacity, system speed and precision, and environmental factors such as temperature, humidity, and vibration. These factors play a critical role in ensuring the optimal performance of the gantry system for a specific application.

What are some common applications of gantry systems?

Gantry systems are widely used in various industries, with applications ranging from manufacturing and assembly, material handling, and logistics, to robotics and automation. They are particularly valuable in applications that require high precision, speed, and flexibility in industries such as automotive, pharmaceutical, energy, semiconductor, aerospace, manufacturing, and more.

Can gantry systems be customized for specific applications?

Yes, gantry systems can be customized to meet the unique requirements of different applications. This can involve selecting the appropriate type of gantry system, adjusting load capacity, modifying system speed and precision, and choosing suitable materials and control systems to ensure optimal performance in specific environments.

Conclusion

Gantry systems have proven to be an indispensable technology in various industries, offering unparalleled precision, speed, and flexibility. They have been successfully employed in diverse applications such as manufacturing, assembly, material handling, logistics, and robotics, among others. By understanding the fundamental principles behind gantry systems, their various types, design considerations, and applications, organizations can make informed decisions on how to best utilize this technology to enhance their operations and achieve greater efficiency.

The key to fully leveraging gantry systems is understanding the specific requirements of each application and selecting the appropriate type of gantry system from a large catalog, be it Cartesian, polar, or cylindrical. Moreover, carefully considering factors such as load capacity, system speed, precision, and environmental conditions can further ensure the optimal performance of the gantry system in any given application.

As industries continue to evolve and adapt to new technologies, the importance of gantry systems is expected to grow, with further advancements in control systems, materials, and designs paving the way for even more innovative applications and solutions.

Post time: May-20-2024