The drive for automation has been a key part of processing and manufacturing since the industrial revolution, with manufacturers looking to create efficiencies, reduce costs and free up people to allow them to put their skills to best use.

With the momentum through Industry 4.0 and the IIoT helping to drive automation, solutions are becoming slicker, more reliable and are providing immediately measurable results. We take a look at linear automation products such as linear rails and linear ball screws, and find out how they fit in to the IIoT.

What is the IIoT?

The IIoT (industrial internet of things) is an extension of the more commonly used internet of things (IoT), but with a focus on industrial settings. The concept behind the IIoT is that businesses and industries as a whole should be able to achieve better efficiencies and more reliable output and service through the use of machine-to-machine (M2M) communication, big data, and machine learning.

How is the IIoT driving automation?

Automation is a trend which is rapidly picking up pace, pushed on significantly by the pandemic over the past year as the shift toward greater automation became, and is predicted to remain, a trend within businesses of all sizes. It is impacting every part of the way in which businesses function, from customer engagement, KPIs and management techniques and goals, as well as RPA (robotic process automation) where the need for human intervention is removed from repetitive tasks, therefore also removing the potential for human error. The point about automation is that it doesn’t just remove the risk of error, it also creates faster, more efficient processes – and the same is true of industrial automation.

How will linear automation products be used within automated environments?

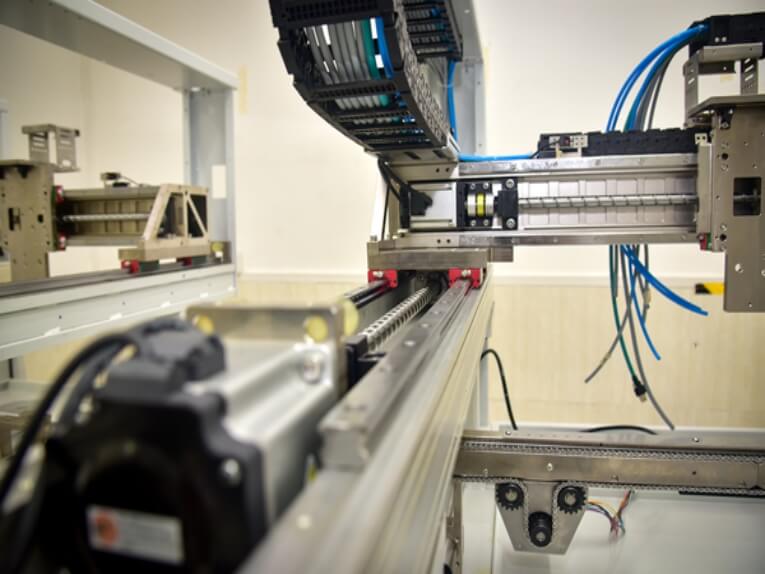

Almost every aspect of production automation in industrial systems relies on a motion control system. Linear motion control systems provide an accurate and repeatable motion in a straight-line. Whilst the actuators are responsible for the conversion of energy into motion, the linear rails provide the guidance and structural support for that movement.

As with industry around the globe, in the UK linear rails are a critical element of linear automation products. Examples of usage of UK linear rails in an automated environment could include gantry robots for positioning loads, pick and place operations and filling operations in automated warehouses, cutting equipment as part of a production line, valve operation and process control.

How could a linear ball screw be used as part of an automation process?

A linear ball screw turns rotational movement into linear movement in a very precise and repeatable way. A threaded shaft provides a helical path for ball bearings which behave like a screw whilst providing minimal friction. If the shaft of the linear ball screw is driven by a stepper motor then the nut can be located with extreme precision, at high speed and very reliably. Any load or tooling attached to nut can then be made – via motion control – to replicate any linear action usually performed by hand. Multiple axis can be achieved by combining several threads to provide many degrees of freedom in 2- or even 3-dimensional space. Linear ball screws provide accurate, fast, reliable movement in a way that a person could not hope to achieve manually. When set up and used in the right way – integrated through IIoT with other automated systems – linear automation products such as linear ball screws are key to ensuring that processing and manufacturing environments run efficiently and with precision, improving output levels and, ultimately, providing operations that will be able to compete within a global marketplace which is fast becoming dominated by automated businesses that embrace Industry 4.0.

Post time: Nov-13-2023