-

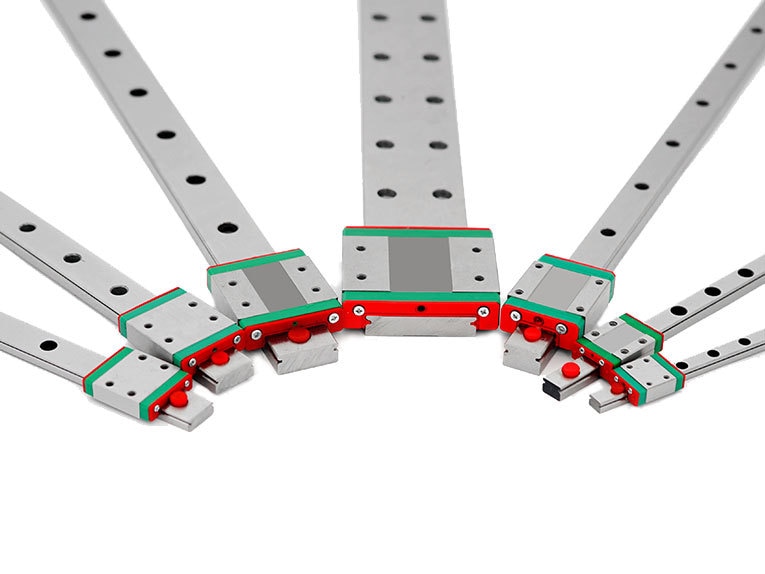

Three efficient ways to reduce maintenance costs for linear systems

Replacing a linear guide carriage or replacing a full carriage and rail assembly. Inadequate lubrication can cause bearing failure. But while lubrication is the most important maintenance factor in linear bearing life, there are other things that users can do to reduce maintenance costs and ensu...Read more -

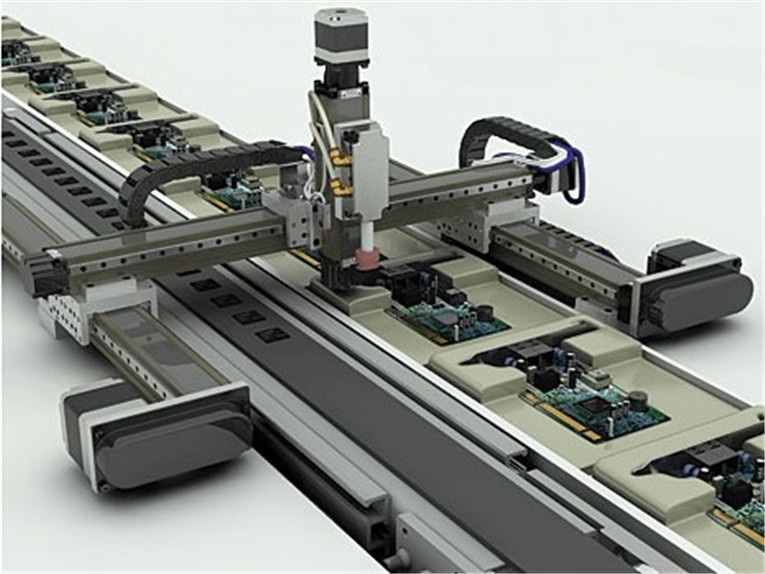

4 Primary Application Parameters—Stroke, Load, Speed and Precision

Gone are the days when machine designers and builders had to choose between constructing their own linear system from scratch or settling for a limited range of pre-assembled systems that, in most cases, were an imperfect fit for their application. Manufacturers today offer systems based on a ra...Read more -

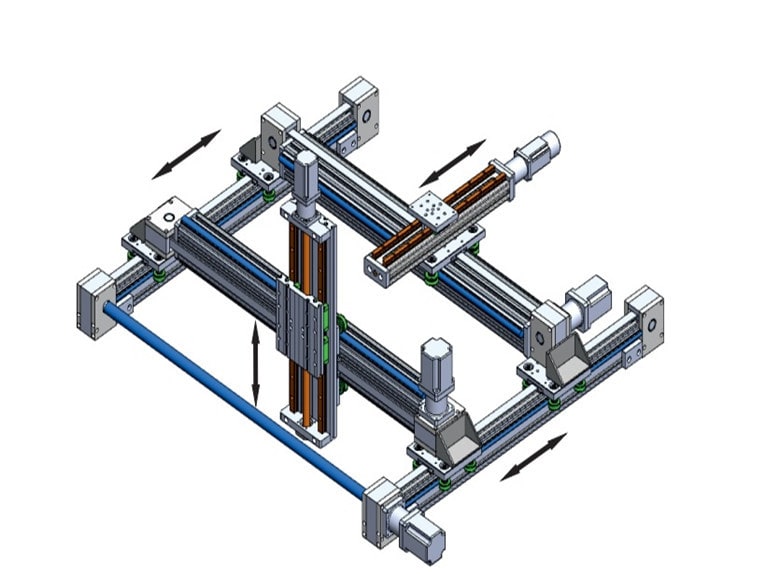

How to design a linear-motion system?

High efficiency, accuracy and stiffness. The shortest path between two points is a straight line. But if you’re designing a linear-motion system, you’ll have to consider structural support, guides, drives, seals, lubrication, and accessories between points A and B. Whether you decide to design a...Read more -

Seven Key Parameters to Design an Optimal, Cost-effective Linear Motion System

Load, Orientation, Speed, Travel, Precision, Environment and Duty Cycle. Careful analysis of the application, including orientation, moment and acceleration, will reveal the load that must be supported. Sometimes, the actual load will vary from the calculated load, so engineers must consider the...Read more -

Innovative Servo Drive Suppresses Vibrations

Suppressing Vibration Dramatically Reduces Settling Time. In a high-speed pick-and-place operation, settling time is the enemy of productivity. Speed is essential for high-volume assembly. However, speed also creates problems. In a pick-and-place operation, for example, moving quickly from side ...Read more -

Don’t overlook these factors when choosing a linear system

Movement Life Means a Lot. When sizing a linear system, the first application parameters that come to mind are probably travel, load, and speed. In addition, details about the load’s placement, the move profile, and the duty cycle are needed in order to accurately calculate the bearing’s useful ...Read more -

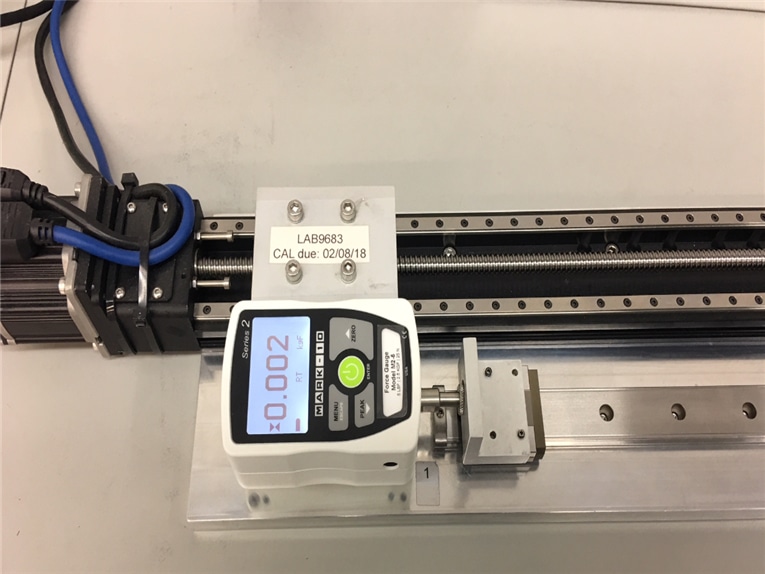

Three Easy Ways to Reduce Maintenance Costs for Linear Systems

【Look and Listen】 Once the system is installed, tuned, and run-in, pay attention to any changes in running smoothness or noise. Rough running can indicate excess contamination or damage to bearing surfaces, while an increase in running torque often signals extreme wear. Noise has several poten...Read more -

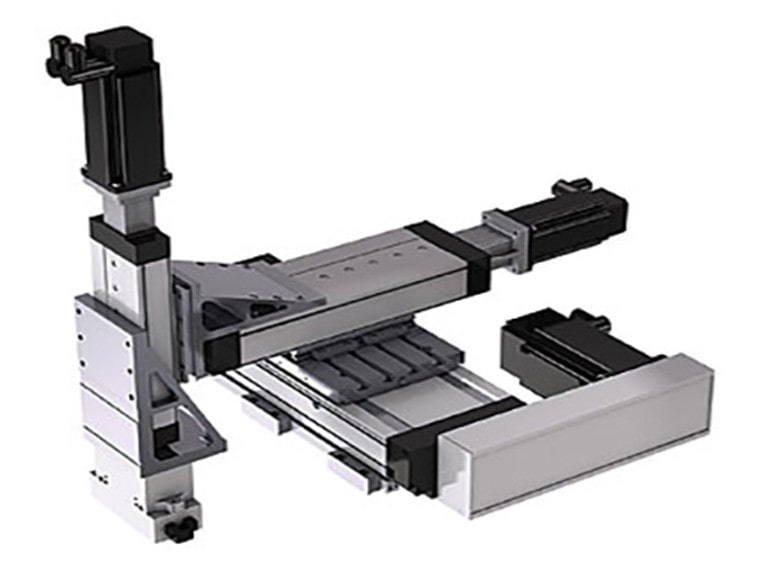

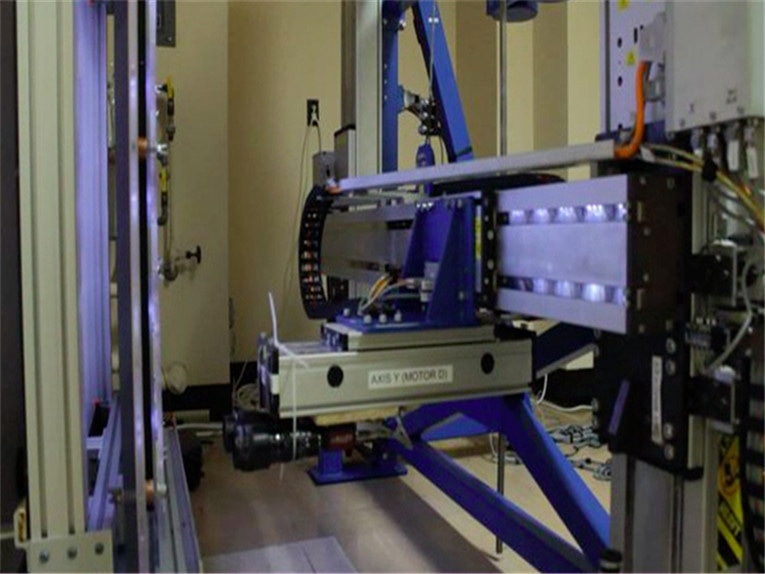

Where Linear Motors Improve Designs: Application Example in Multi-axis Stage

A Robotic Control XYZ Gantry Machine-tool applications and the manufacture and assembly of semiconductor components account for more than half of all linear-motor use. That’s because linear motors are precise (albeit costly compared to other linear-motion options). Other applications for these r...Read more -

How Many Axes Should My Robot Have?

If you have already shopped for a robot you have probably already been confronted with the number of axes that are included in the robot. Perhaps, if you are new to the robotic world you may wonder: What this all means? and Why is it important how many axes my robot has? Robots will have 3 to 7...Read more -

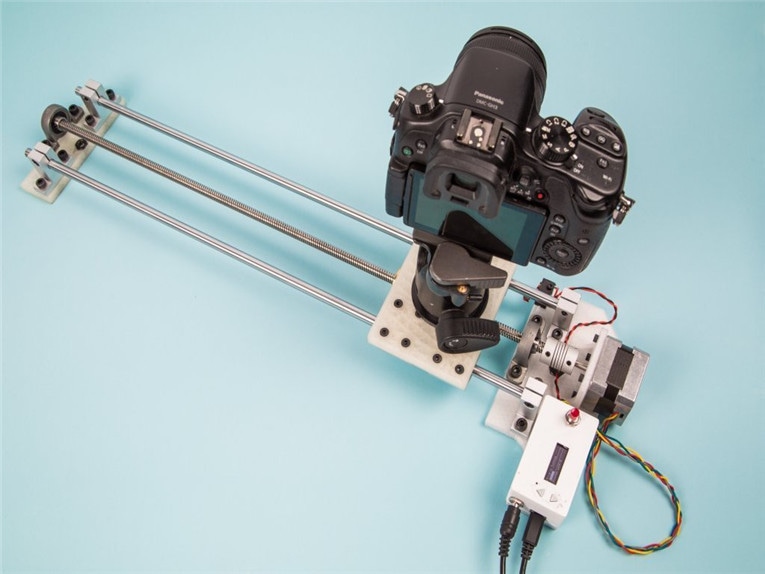

Capture Moving Timelapse Video with this Motion Control Camera Slider

single-axis linear motion system I’ve enjoyed capturing timelapse videos ever since I found myself in possession of a camera that could do them. I love the way they transform the mundane into the surreal, whether it’s the ability to see a transformation taking place that’s too slow to observe wi...Read more -

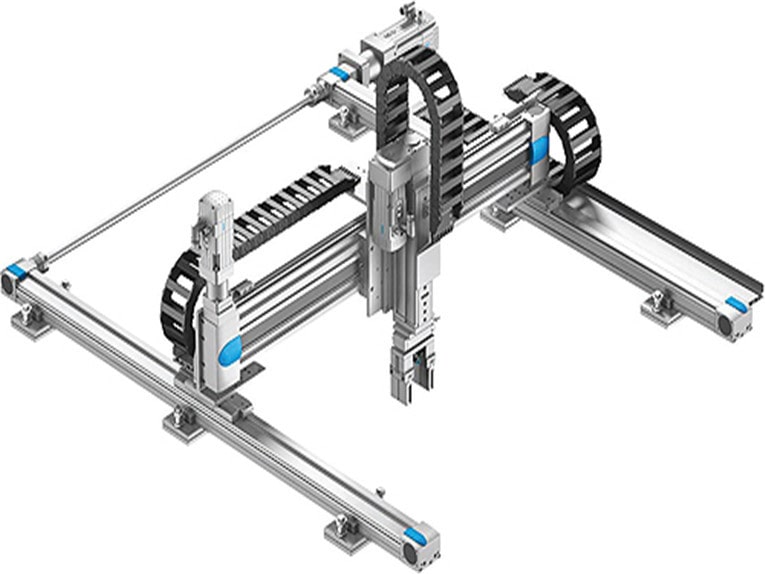

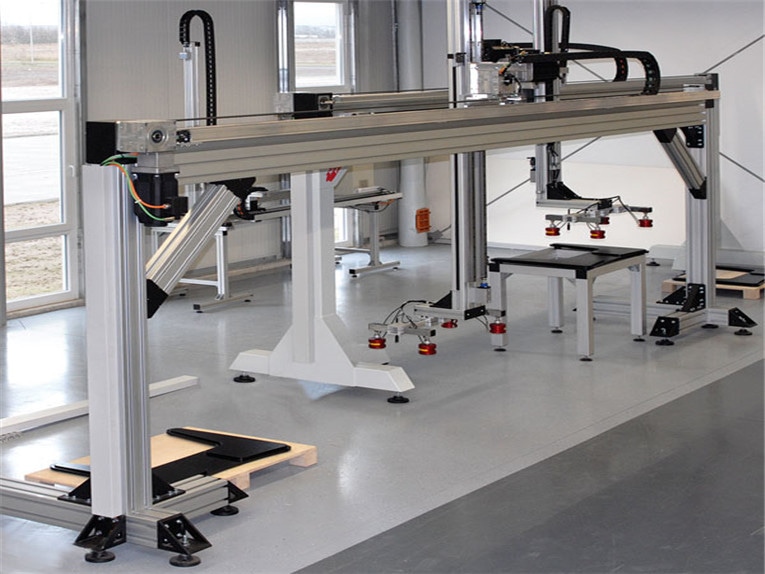

Cartesian Handling System: 2D Motion & 3D Motion

Customization and Versatility Cartesian handling systems as serial kinematics have main axes for straight-line motion and auxiliary axes for rotation. The system acts simultaneously as guide, support and drive and must be integrated into the application’s complete system regardless of the handli...Read more -

What Questions Should You Ask During the Product Lifecycle?

There are four phases of a product’s lifecycle. When you’re in the business of manufacturing, it’s important to know exactly why you’re doing what you’re doing and to leave nothing to chance. There are too many resources invested across the entire manufacturing process to be flippant about it. T...Read more