-

What are Can Stack Linear Actuators?

Can stack linear actuators are based on can stack stepper motors, which are a form of permanent magnet steppers that consist of two stators (and therefore two coils) stacked on top of each other. The poles of each stator are “claw tooth” design and are offset from each other by one-half of the p...Read more -

What are Common Applications for Hybrid Stepper Motor Linear Actuators?

The hybrid stepper motor linear actuator provides good force and speed capabilities with high positioning accuracy. When it comes to electromechanical linear actuators, integrated designs offer space savings, reduced complexity, and lower total cost of ownership with fewer parts required for rep...Read more -

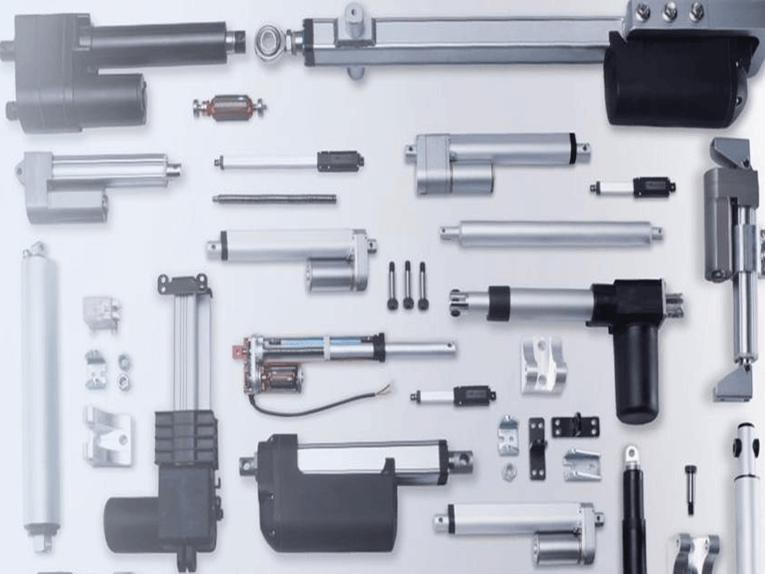

Linear Actuator Industry Solutions for Positioning System

Industrial Automation FUYU is committed to providing customers with high-performance and more reasonable industrial automation solutions. Industrial series linear actuator has strong corrosion resistance, high sealing and waterproofing and can beusedfora long time in harsh environment. Medical A...Read more -

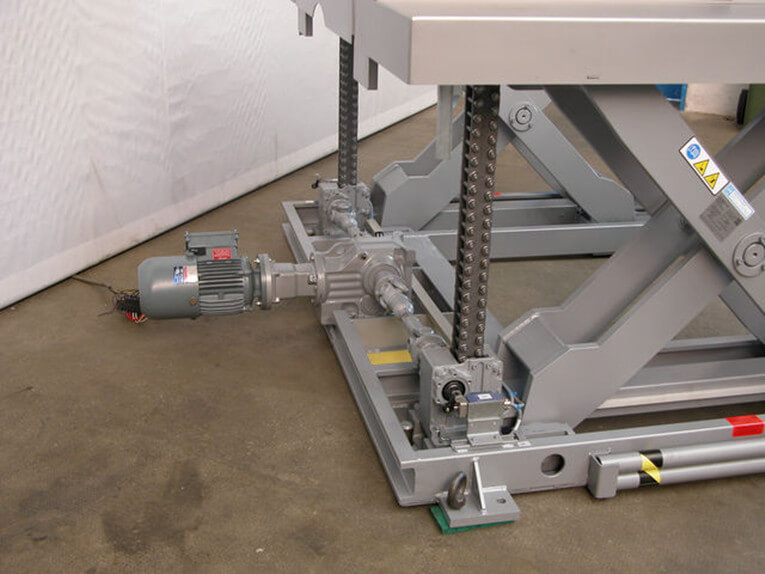

Linear Actuator Designs for Vertical Lifts: What are Pitfalls to Avoid During Jack-system Design?

Linear actuator designs for vertical lifts often take the form of worm screw jacks. There are several criteria by which a worm screw jack can be sized properly — six primary factors, to be exact. First is the basic tonnage rating of the jack. This is simply the overall capacity that a jack can ...Read more -

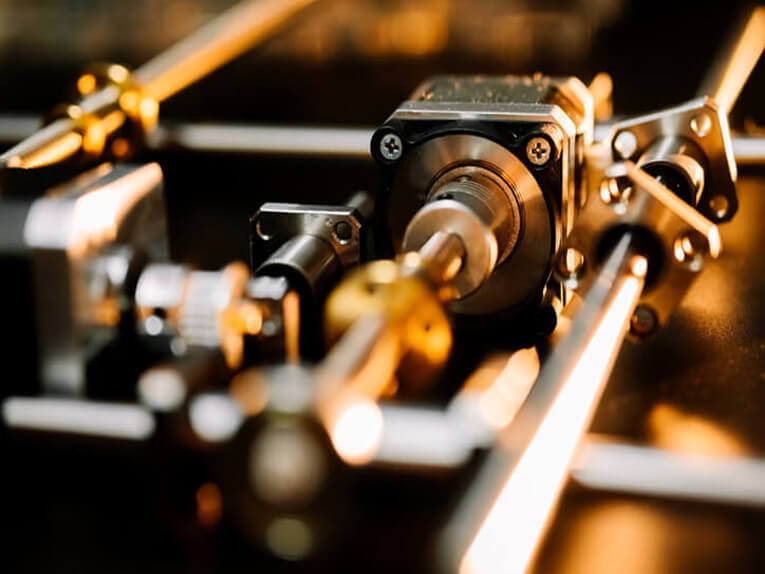

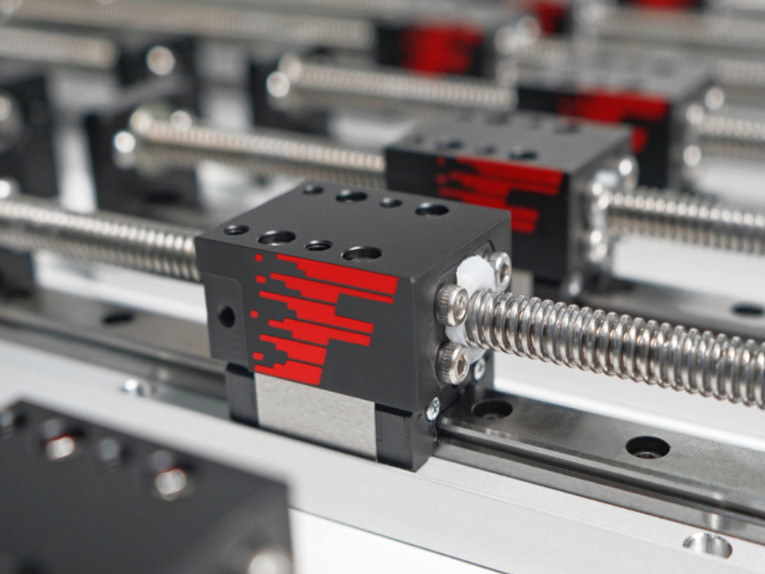

Screw-driven or belt-driven linear actuator?

How to choose the right linear actuator? Linear actuators are an important element in automation and mechanical engineering and help with a variety of tasks, from simple to extremely complex ones. Picking the right one is very important, since linear actuators and linear slides can be driven in ...Read more -

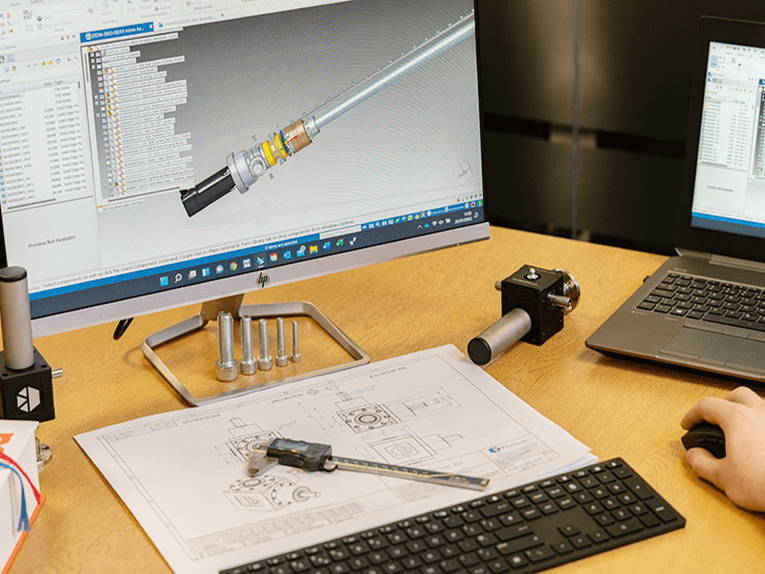

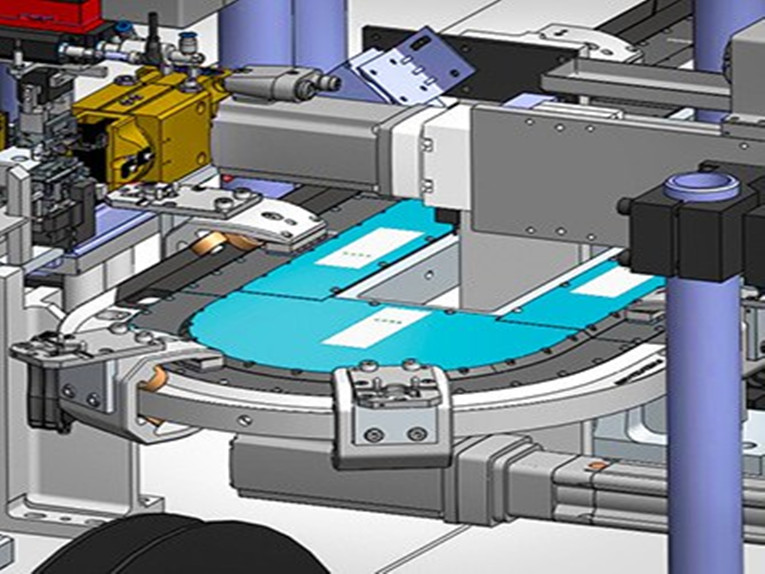

Multi-axis Stages and Tables: Manufacturer Involvement and Software Yield Turnkey Motion Systems

There’s increasing demand for stages, tables, gantries, and indexing tables with simplicity or turnkey operation — largely because of industry moves toward focused expertise and abstraction. No wonder that motion-system manufacturers are now doing more integration for plant engineers and OEMs. A...Read more -

What’s the difference between a vertical lift stage and a Z axis actuator?

In many applications that require vertical motion, a Z axis actuator is combined with one or two horizontal axes in a Cartesian or gantry-style arrangement. In these multi-axis configurations, the moved load is mounted to the Z axis via a bracket, creating a moment load that affects not only the...Read more -

How are multi-axis sensors improving product development?

With a multi–axis sensor design, a single load cell sensor can measure 3 axes of force and 3 torque moments simultaneously. These sensors consist of multiple bridges that precisely measure the applied force from one direction with minimal crosstalk from the other axes. Using a multi-axis sensor,...Read more -

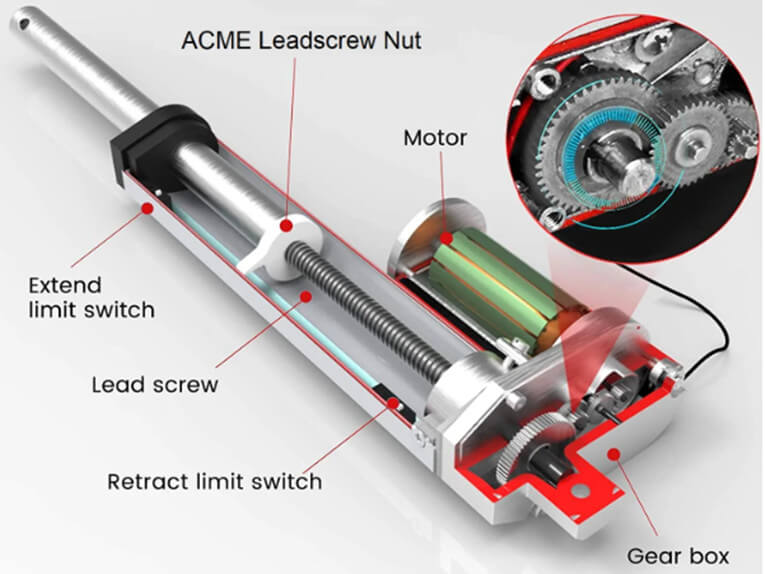

Selecting the Proper Motor for Linear Motion Applications

Linear motion systems are found inside countless machines including precision laser cutting systems, laboratory automation equipment, semiconductor fabrication machines, CNC machines, factory automation, and many others too numerous to list. They range from the relatively simple such as an inexp...Read more -

How to Move Medtech Manufacturing into the Future

“Factory of the future” systems can enable expanded and more versatile automation solutions, allowing device manufacturers to build their process steps, process speed and process cycles around the system’s capabilities. Medical device manufacturing processes tend to be highly regulated, requirin...Read more -

Total cost of ownership for linear motion

You may not realize it, but many of the products you buy actually cost a lot more than the initial price you paid for them. For example, let’s say you paid $25,000 for your vehicle. How far do you drive and how many gallons of gasoline do you use each week? How often do you change the oil,...Read more -

A Guide to Stainless Steels for Linear Motion Components

For applications that involve corrosive environments, designers of linear motion systems can take precautions such as using covers to protect vulnerable components, ordering parts with special coatings or platings, and strategically placing sensitive components within the machine or system to mi...Read more