Industrial robots are automated machines that are used in manufacturing industries in the place of human beings. They are faster, more precise and can run for days, qualities that are behind their gradual rise in the manufacturing world. Industrial robots can be classified into 7 main categories discussed below.

Articulated Robots

Articulated robots are the most commonly used robots in manufacturing and they are characterized by rotary joints called axes. They range from simple 2-axis joints to sophisticated ones with more than 10-axis that are powered by motors. The most common articulated robots you would typically find in a factory is a 6-axis robot.

Thanks to their axes, articulated robots are the most flexible and are therefore used in roles that require intense multitasking work. You will find them in welding, parts transfer, assembly, pick and place, packaging and palletizing tasks.

Cylindrical Robots

These are robots that have a single rotary joint at their base and another prismatic joint that connects the links. This rotary joint utilises rotational motion along the joint axis as the prismatic joint uses linear motion. What gives them the name cylindrical however is the shape of their envelope that is shaped like a cylinder. Some of the rules that are best suited for cylindrical robots include robotic coating and machine tending.

Cartesian Robots

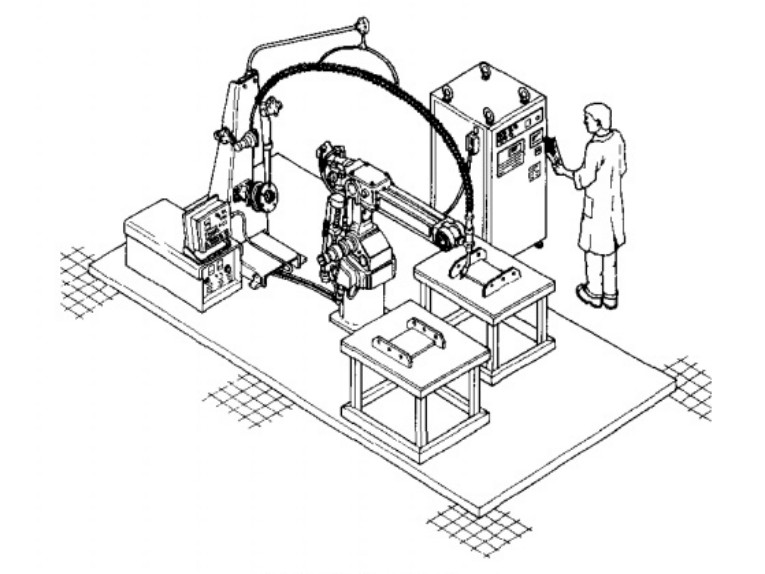

As the name implies, cartesian robots operate along a linear track system. Also known as Gantry robots, they have a cube-shaped envelope that has three perpendicular axes of X, Y and Z. It is these axes that determine each directional movement of the robot during operations. Cartesian robots are best suited for pick and place roles because they can cover very huge distances, depending on the length of the linear tack. Most of the line tracks are usually overhead which also makes these types of robots the best for making use of space.

SCARA Robots

SCARA Robots are among the most advanced industrial robots. They are best known for their speeds which is the reason why they are given sophisticated roles like assembling intricate parts of cars and other automotive contraptions. They have a cylindrical envelope and can also operate along an X,Y,Z plane coupled with a rotary motion. Other roles that SCARA robots can conotably handle include machine loading, palletizing, and automated packaging.

Collaborative Robots

Collaborative robots were the answer when the need to include human labour alongside robots arose. They are designed with the best safety features that makes them ideal to work alongside humans without any danger of accidents taking place. They are rounded without any point and are equipped with state of the art sensors that are able to determine distances when humans are in proximity.

Delta Robots

Also called Parallel robots, these are automated industrial machines that feature parallele joint arms that extend from a common base facing downwards. It has a dome-shaped envelope. Their extremely lightweight arms makes them the ideal robot for tasks that require high seeds with equal precision. They are the type of robots you will find in an electronic manufacturing factory, food processing plants or a pharmaceutical maker. Their roles include pick and place and parts transfer.

Polar Robots

Polar robots were the first industrial robots to be invented; most of the improved robots that came after them were roughly based on the Polar robot blueprints. They have a spherical work envelope and polar coordinate formation of the robot axe. They are not widely used anymore but in places where they have been adapted for modern roles you will find them handling tasks like die casting, injection molding and material handling.

Conclusion

Industrial Robots continue to revolutionize the manufacturing process around the world. They are faster and produce high quality materials. However, the disruption the continued cause in the job market cannot be ignored.

As more manufacturers are switching from human labor to automated machines, it is only a matter of time before thighs get hairy down the line. If manufacturing is what you have been eyeing for a while now, then getting to know all these types of robots and how they work will be a good start for your journey.

Post time: May-22-2023