Double Slides Z Axis Rail Motorized Table Linear Motion Stage Ball Screw Actuator Vertical and Horizontal Positioning Guide System

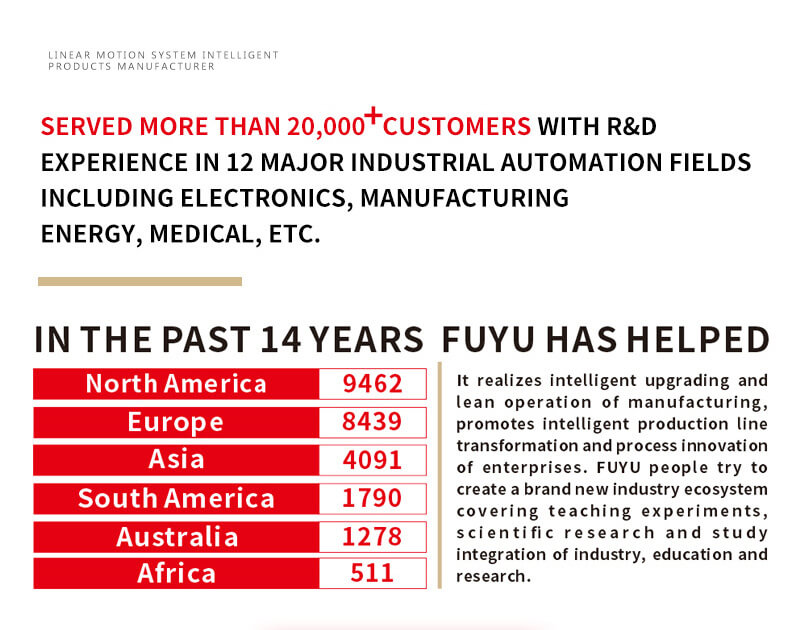

FUYU Technology specializes in industry-specific customization and we are a brand manufacturer of Intelligent linear motion systems. Our products include Ball Screw Actuator, Belt Driven Module, XYZ Positioning Stage, Gantry System, Sever Cylinder, Linear Rail Guide, Electric Gripper and Multi-axis Motion Controller for Cartesian Robot. The engineer team has 8 invention patents, 47 utility model patents, 24 design patents, 18 software copyrights. The factory is awarded industry certifications such as ISO9001:2015, ROHS, CE, FCC and TUV. Since 2011 founded, we have served more than 26400 customers all over the world with linear motion system none-standard solutions covering 9 major fields, including 3C electronics, biological science, new energy, medical equipment, smart food, agriculture automation, automotive industry, visual inspection, education research and so on. The company owns wide variety of ready-to-Ship products, we also accept OEM orders and supply programming services. Based on thousands of successful industry solutions, advanced engineer development concepts and efficient assembly team for linear motion workbench, we sincerely invite the global partners to share new source, new price and new chance. “Your Idea, Our Motivation.” Let's make it together!