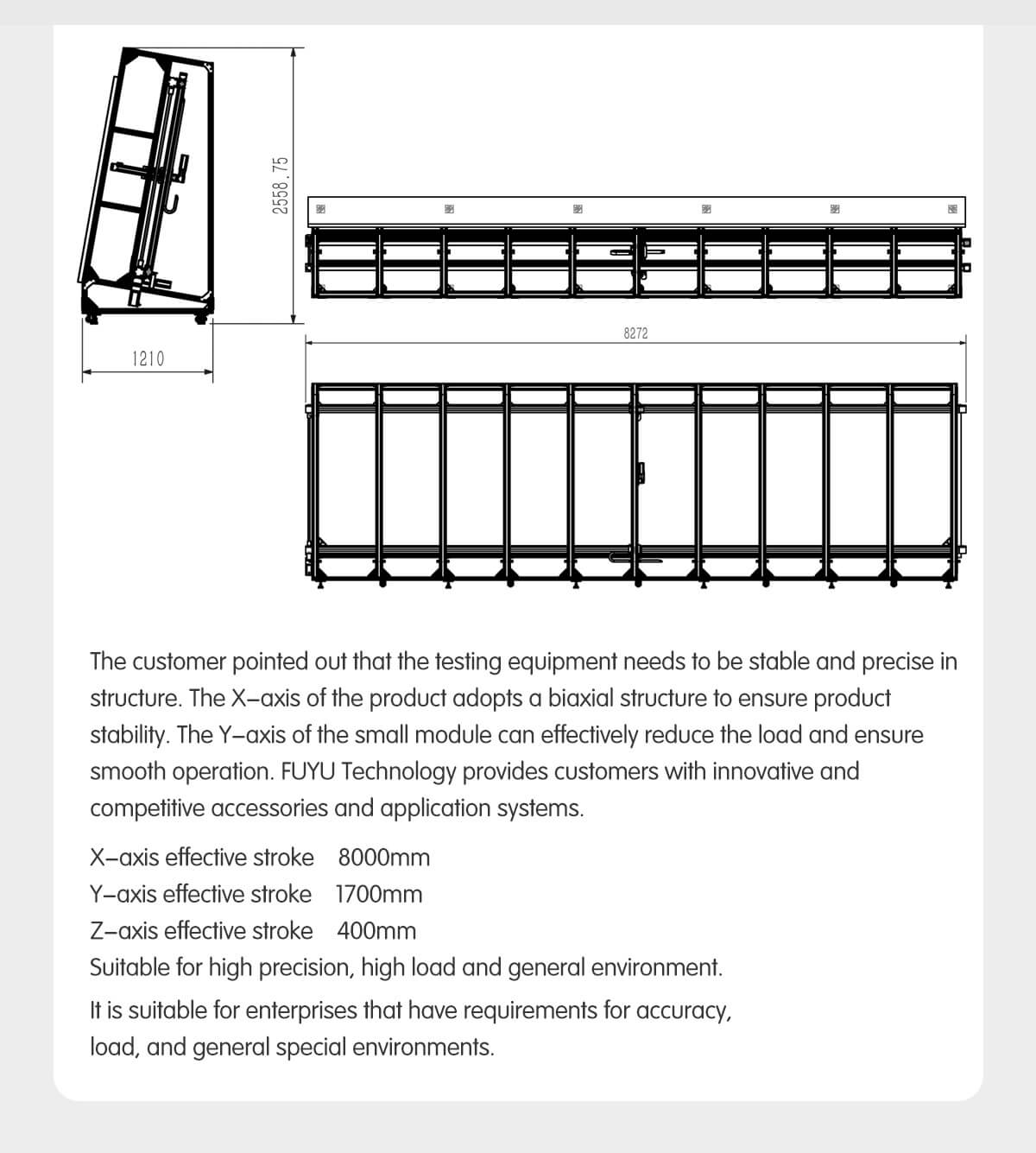

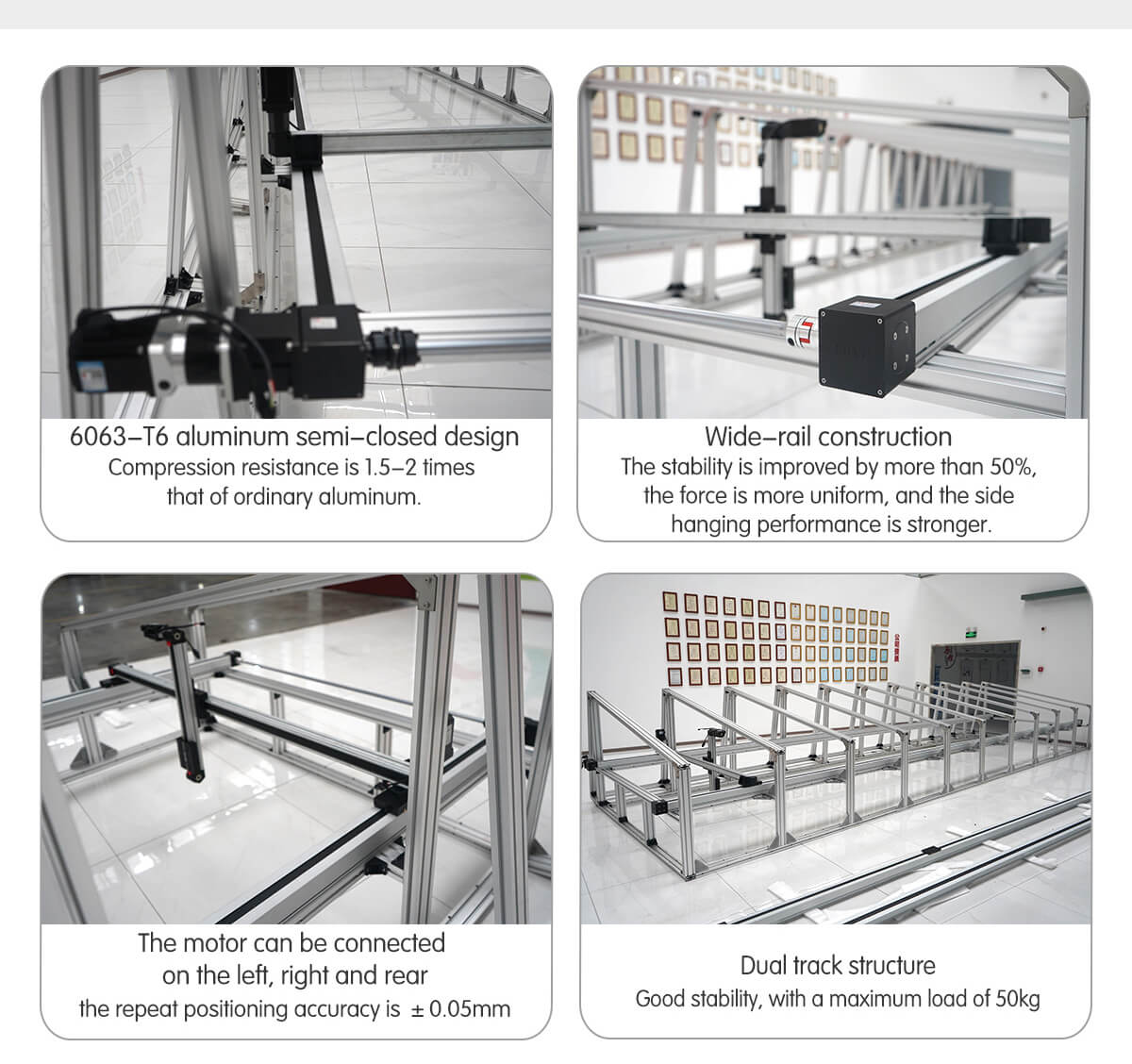

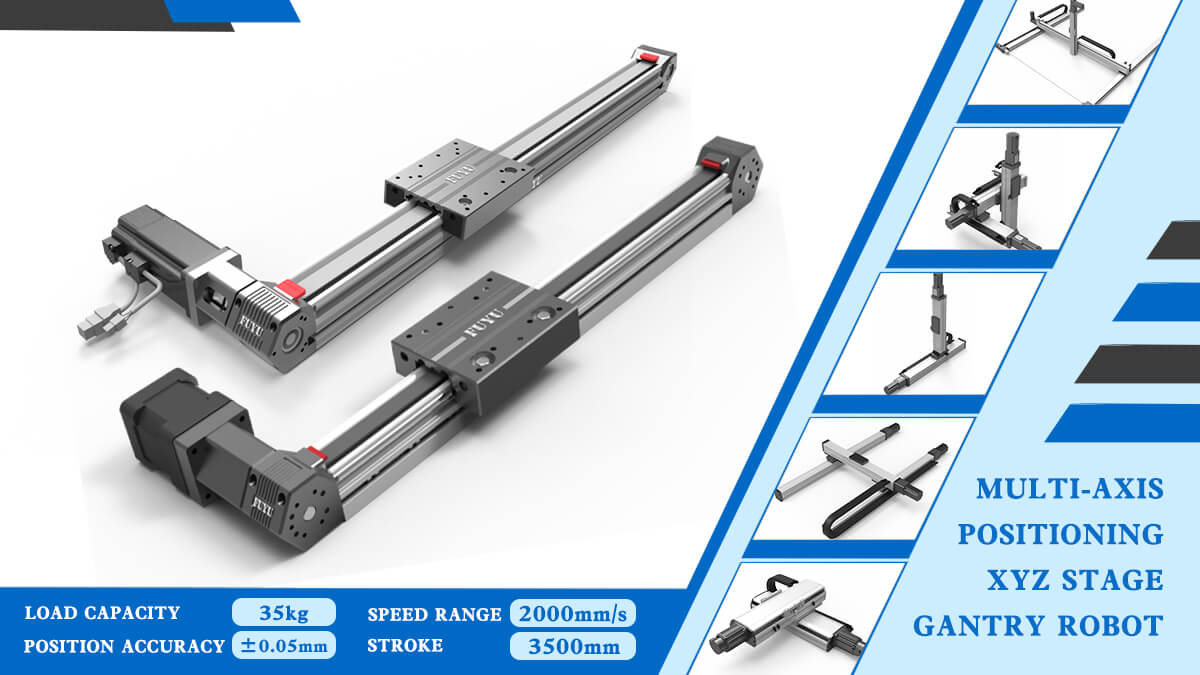

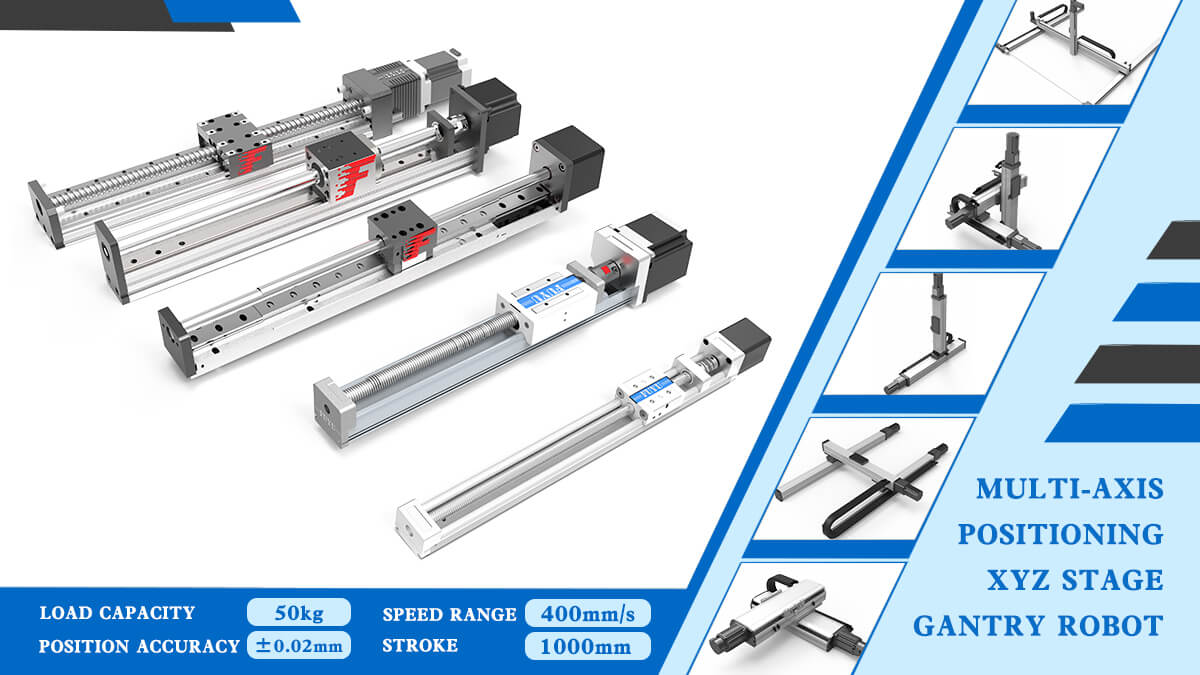

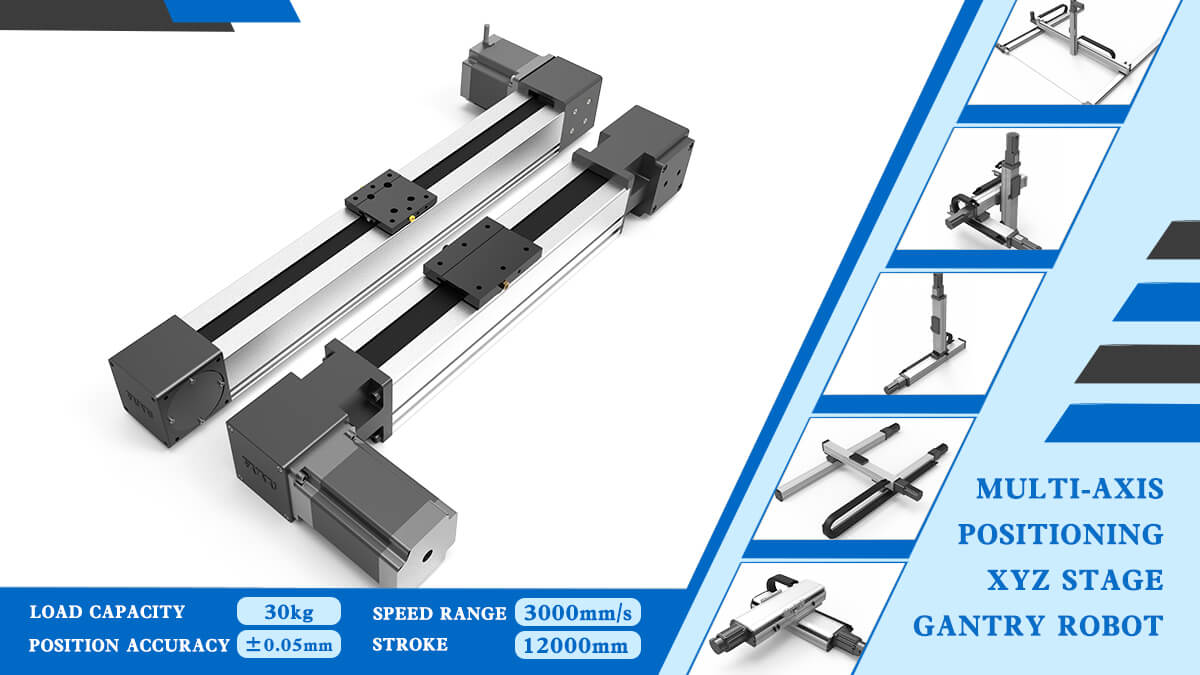

Linear Motion XYZ Stage Gantry Robot Multi-axis Positioning Guide System Belt Driven Actuator

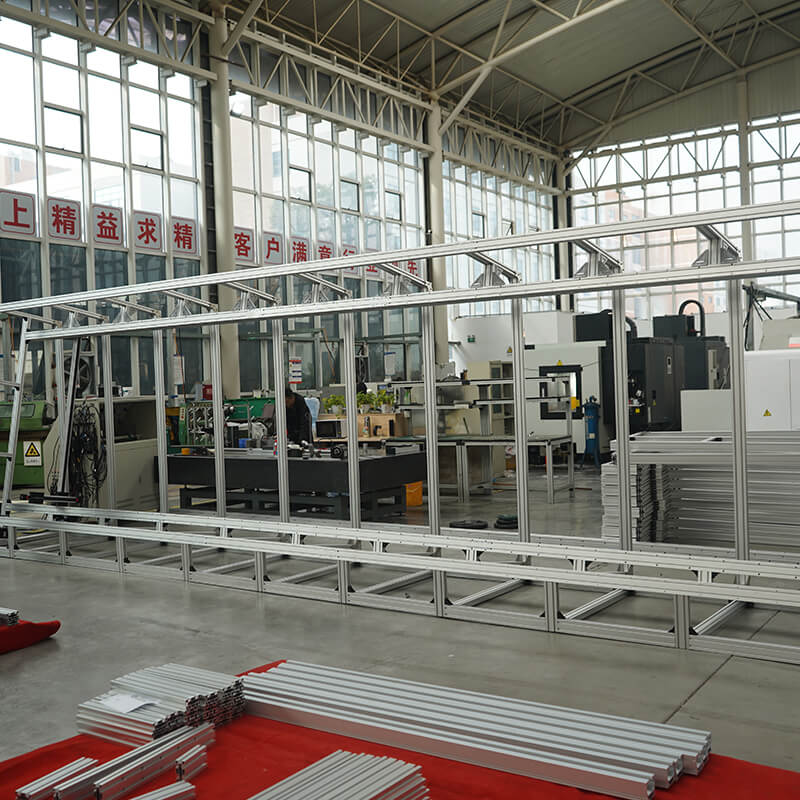

CHENGDU FUYU TECHNOLOGY CO.LTD

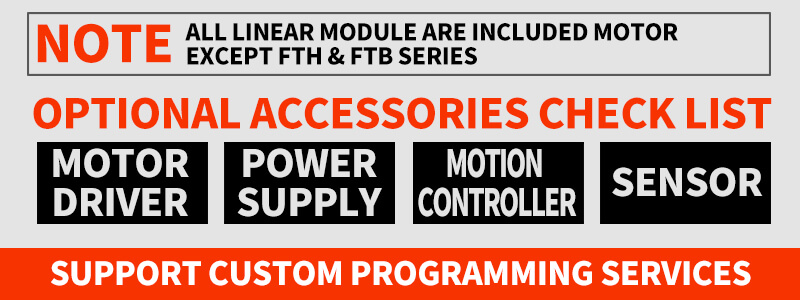

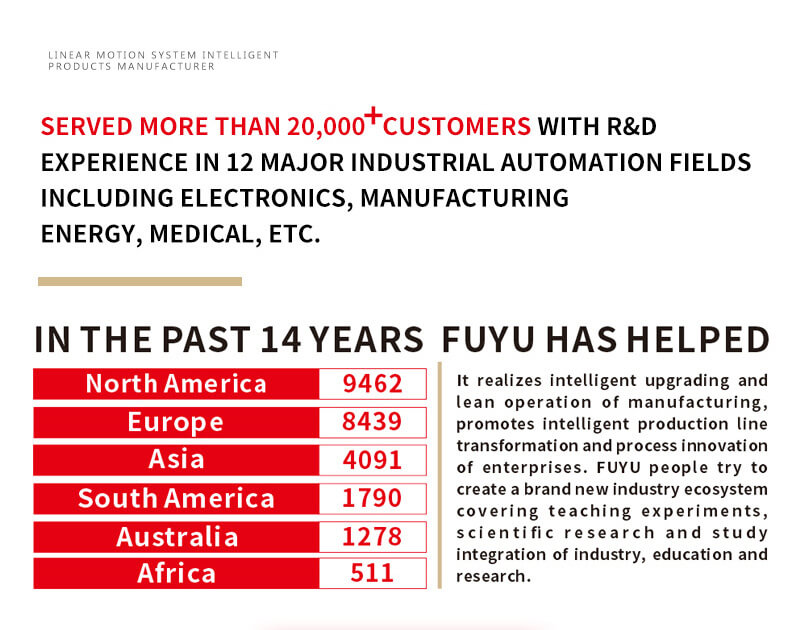

FUYU is a Linear Motion System Intelligent Products Manufacturer. Our main products include Ball Screw Linear Module, Belt Driven Linear Guide Rail,Electric Actuator, Positioning Stage and Motion Controller for Cartesian Robot.As a National High Tech Enterprise, 82 intellectual property rights have been authorized, involving 6 invention patents, utility models, appearance patents and 76 software copyrights. We are certificated by CE, FCC, RoHS, TUV and ISO9001.Multi-axis Positioning System can be composed of several modules, Stroke Range 50mm-12000mm, Position Accuracy 0.02mm-0.2mm and Load Capacity 3kg-180kg. They are widely used for Medical Equipment, Automation Products Line, Electronic Industry and etc.As an Industrial Factory, we also accept OEM. Once you provide the machine design, our engineers will contact in 48 hours to suggest the best solution for the linear motion system.

Write your message here and send it to us