What is a Cartesian Robot?

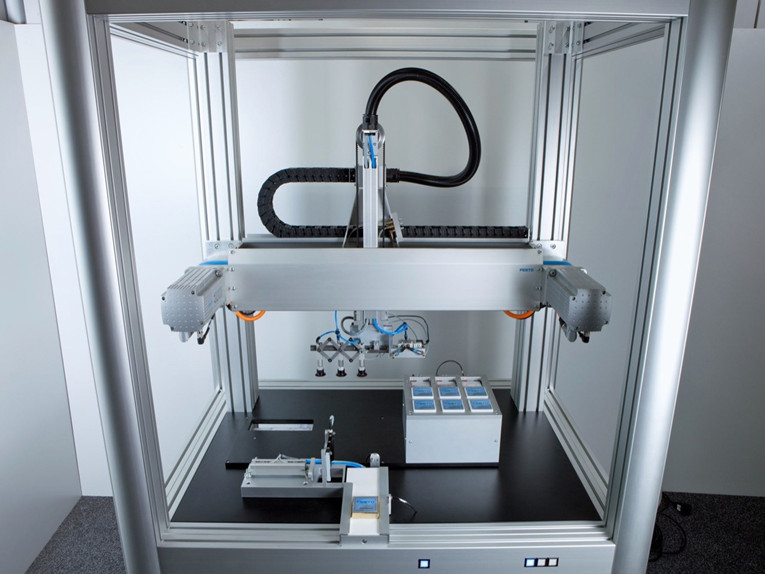

Machines that operate on Cartesian coordinate systems have been staples in factories for decades. 3D printers, laser-cutters, and CNC machines are examples of devices that use the same principle as Cartesian robots. What sets these robots apart from others is their construction. Cartesian robots are boxy, open, and their primary X-Y directional motion is regulated from above by a rectangular gantry. A lead screw or other linear actuator controls movement in the vertical, Z-direction. All Cartesian robots have this rectangular configuration, and as a result, they are sometimes called rectilinear robots or gantry robots.

The Benefits: Strength, Precision, and Accuracy.

Thanks to their rigid structure and boxy configuration, Cartesian robots can carry heavy loads. They are excellent at performing pick-and-place tasks, loading and unloading, material handling, and even high precision operations.

When it comes to accuracy, however, several factors determine how well a Cartesian robot will perform over time. If the drive system uses a rubber belt, for example, it may stretch or underperform with loads above a certain weight. Motor encoders, servos, and stepper motors improve travel accuracy as long as the material components are regularly checked or calibrated. Under optimal conditions, a Cartesian robot will exhibit superb accuracy in addition to its other qualities. However, do your due diligence before making a purchase and ensure the materials will withstand regular use.

Work Envelope of a Cartesian Robot

A Cartesian robot’s work envelope is defined by its rectangular structure. Often there is a plate or work area within the boundaries of the X-Y plane. The operational height is bound by the vertical ceiling and the plate or work area. Within this area, there are no “dead zones.” The Cartesian robot has access to every part of the payload that is within this operational cube. The footprint of a cartesian robot is rectangular and compact. SCARA robots and six-axis robots have oblong work envelopes that create a lot of unusable space around them. Thanks to the predictable, measurable, and well-defined boundaries of the Cartesian robot, factories can incorporate them easily into their existing infrastructure without having to do a lot of calculating first.

What’s the price of a Cartesian Robot?

Due to their simplistic design, primary motor controller, and minimal moving parts, Cartesian robots provide savings over articulated robots. You will also save money by reducing downtime associated with start-up, programming, and troubleshooting. However, articulated robots are more flexible in the long-run. So while you’ll see a lower sticker-price on some Cartesian models, that discount comes at the cost of versatility.

Post time: Nov-01-2021